Understanding NTC Resistors: Principles, Applications & Selection

In our daily lives, from the smartphone in your pocket to the sophisticated machinery in a factory, accurate temperature sensing is crucial. At the heart of many of these systems lies the humble NTC resistor, a component whose resistance changes inversely with temperature. This article delves into the world of NTC resistors, explaining their functionality, wide array of applications, and how to select the right one for your needs.

What is an NTC Resistor?

An NTC (Negative Temperature Coefficient) resistor, often referred to as an NTC thermistor, is a type of resistor whose electrical resistance decreases as its temperature increases. This inverse relationship between temperature and resistance is the fundamental characteristic that defines NTC resistors and makes them invaluable in various electronic applications, particularly those involving temperature sensing and control.

How NTC Resistors Work: The Underlying Principle

NTC (Negative Temperature Coefficient) resistors exhibit a characteristic decrease in electrical resistance as their temperature increases. This behavior stems from the intrinsic properties of the semiconducting materials they are composed of, typically metal oxides. The fundamental principle involves the increased thermal excitation of electrons within the material, leading to a greater availability of charge carriers and, consequently, enhanced electrical conductivity and reduced resistance.

The relationship between resistance and temperature in an NTC thermistor is non-linear and is often described by the Steinhart-Hart equation or a simplified exponential model. The 'B-constant' (β) is a material-specific parameter that quantifies the extent of this change. A higher β-value indicates a more significant resistance change for a given temperature variation.

| Property | Description |

|---|---|

| Temperature Coefficient | Negative, resistance decreases with increasing temperature |

| Relationship | Non-linear, often described by exponential or Steinhart-Hart models |

| Mechanism | Increased thermal excitation of electrons, resulting in more charge carriers |

| Key Parameter | B-constant (β), which quantifies the sensitivity of the NTC resistor |

NTC Resistor Applications: Where are They Used?

NTC resistors, owing to their characteristic of decreasing resistance with increasing temperature, find widespread use in various applications. Their ability to precisely respond to thermal changes makes them invaluable for temperature sensing, control, and protection across diverse industries. These applications range from simple temperature measurement to complex thermal management systems, highlighting their versatility.

- Temperature Sensing

NTC thermistors are extensively used as temperature sensors in a wide array of devices, including digital thermometers, HVAC (Heating, Ventilation, and Air Conditioning) systems, and automotive temperature monitoring systems. They provide a cost-effective and accurate way to measure temperature. - Inrush Current Limiting

When electronic devices are powered on, they can experience a surge of current known as inrush current. NTC resistors, placed in series with the power supply, limit this inrush current by having high resistance when cold. As current flows, they heat up, their resistance decreases, and they allow normal operating current to pass through. - Temperature Compensation

In circuits where temperature changes can affect performance, NTC resistors are used to compensate for these effects. They help maintain consistent circuit operation by counteracting the temperature-induced variations in other components. - Thermal Protection

NTC resistors are used in thermal protection circuits in batteries, power supplies, and other devices. They monitor temperature and can trigger a shut-down or alarm if temperatures become too high, preventing damage or hazardous conditions. - Automotive Applications

They are widely used in automotive systems for temperature monitoring in engines, transmissions, passenger compartments and battery management, enabling the control of various systems and ensuring optimal performance and safety. - Medical Devices

NTC thermistors are found in a variety of medical devices such as patient temperature monitors, and in various instruments requiring precise temperature control. Their accuracy and reliability are critical in medical applications.

NTC Resistor vs. PTC Resistors: Key Differences

NTC (Negative Temperature Coefficient) and PTC (Positive Temperature Coefficient) resistors are both thermistors, meaning their resistance changes with temperature, but they exhibit opposite behaviors. This fundamental difference dictates their respective applications in electronic circuits.

| Feature | NTC Resistor | PTC Resistor |

|---|---|---|

| Temperature Coefficient | Negative: Resistance decreases as temperature increases. | Positive: Resistance increases as temperature increases. |

| Resistance-Temperature Relationship | Non-linear, but generally a rapid decrease in resistance with increasing temperature. | Typically a relatively stable resistance until a transition temperature, after which resistance increases rapidly. |

| Primary Applications | Temperature sensing, inrush current limiting, temperature compensation, thermal protection. | Overcurrent protection, self-resetting fuses, heaters, demagnetization. |

| Typical Materials | Metal oxides (e.g., manganese, nickel, cobalt oxides). | Barium titanate or other ceramic materials with specific doping. |

| Response Time | Fast temperature response, ideal for precise temperature measurements. | Generally slower response time compared to NTCs, which is suitable for overcurrent protection. |

| Resistance at Low Temperature | High resistance at low temperature | Low resistance at low temperature |

The choice between an NTC and a PTC resistor depends on the specific application requirements. NTC resistors are primarily used when a temperature is to be measured precisely or when over temperature protection is necessary. While PTC resistors are mainly used for overcurrent and over temperature protection, and self regulating heating applications.

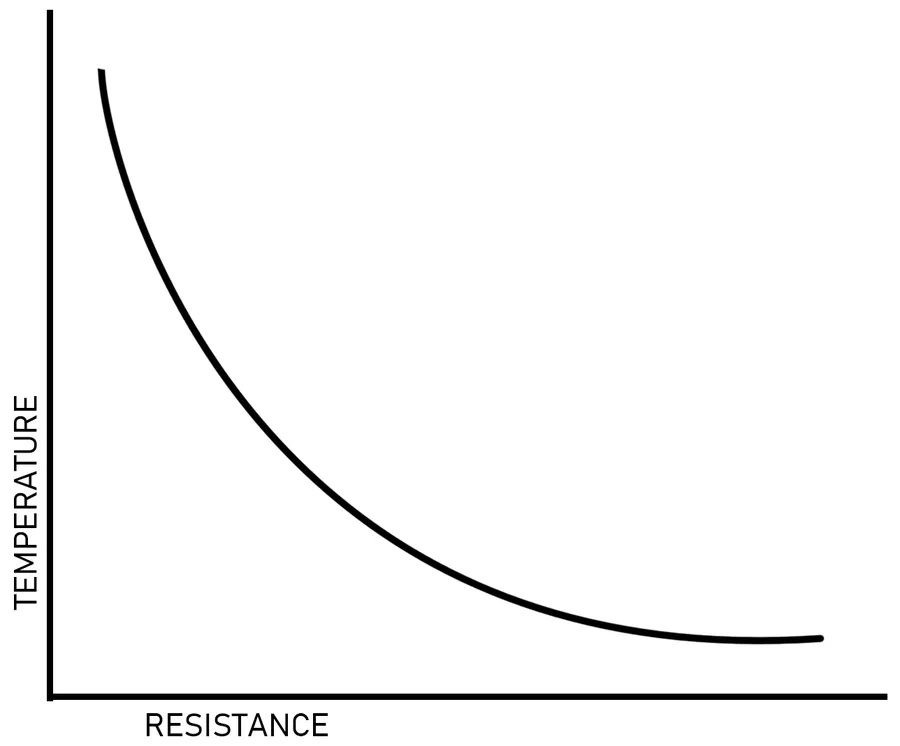

NTC Resistor Resistance and Temperature Curves

NTC thermistors exhibit a characteristic inverse relationship between resistance and temperature, a relationship that is non-linear. This behavior is crucial for their application and is described by various resistance-temperature curves, each tailored for specific operational needs. Understanding these curves is essential for selecting the correct NTC resistor for a given application.

The resistance-temperature relationship is fundamentally exponential, where resistance decreases sharply as the temperature increases. This relationship can be mathematically described by the Steinhart-Hart equation, which offers a high degree of accuracy for representing the NTC's behavior across a wide temperature range. However, simpler models often suffice for specific applications with narrow temperature ranges.

| Curve Type | Description | Typical Application |

|---|---|---|

| Standard Curve | Exhibits a general non-linear relationship, applicable for general-purpose temperature sensing. | Temperature sensing in general electronics. |

| Linearized Curve | Approximates a linear relationship within a specific temperature range, simplifying signal processing. | Precision temperature control and compensation. |

| Custom Curve | Tailored to specific application requirements with unique resistance and temperature range. | Specialized applications, automotive sensing or medical monitoring devices. |

Selecting an NTC thermistor requires careful consideration of its temperature coefficient, which defines how much the resistance changes per degree Celsius. A larger coefficient means greater sensitivity, leading to higher accuracy in temperature measurements. However, it may also result in higher non-linearity. The choice often depends on finding a balance between sensitivity, accuracy, and the specific requirements of the application.

To select an appropriate NTC thermistor based on thermal requirements, one must analyze the specific temperature range of operation, desired sensitivity, and accuracy. Datasheets provide resistance-temperature charts and equations, aiding in this process. It's important to consider the base resistance at a specific temperature, typically 25°C, and the B-constant, which characterizes the temperature coefficient. Analyzing the curves alongside these parameters ensures the NTC is well-matched for its intended purpose.

Selecting the Right NTC Resistor: Key Factors

Selecting the correct NTC resistor for a specific application is crucial for optimal performance and accuracy. This involves careful consideration of several key parameters including the base resistance, B-constant, operating temperature range, physical size, and tolerance. A mismatch in any of these parameters can lead to suboptimal temperature measurement or control, potentially impacting the overall system performance.

| Parameter | Description | Impact on Application | Selection Considerations |

|---|---|---|---|

| Base Resistance (R25) | Resistance value at 25°C. | Affects the sensor's sensitivity and signal-to-noise ratio. | Choose a value that allows for a measurable resistance change within the application's temperature range, and that is compatible with the measurement circuit. |

| B-Constant (β) | Characterizes the relationship between resistance and temperature. A higher β indicates a larger resistance change for a given temperature change. | Determines the sensitivity of the NTC resistor to temperature changes. | Select a value appropriate for the desired temperature range and sensitivity. |

| Operating Temperature Range | The range of temperatures within which the NTC resistor can operate reliably. | Operating outside this range can lead to inaccurate measurements or irreversible damage. | Ensure the range encompasses the full spectrum of temperatures expected in the application. This should include the extreme conditions. |

| Size | The physical dimensions of the NTC resistor. | Impacts physical fit, thermal inertia, and response time. | Match the size to the space available and the thermal response requirements. |

| Tolerance | The permissible deviation from the specified resistance value at 25°C and B-constant. | Affects the measurement accuracy of the sensor. | Choose the level of tolerance appropriate to achieve the required temperature measurement precision. Lower tolerance equals higher accuracy. |

NTC Resistor Wiring and Circuit Integration

Integrating NTC resistors into circuits requires careful consideration of their unique characteristics to accurately measure temperature or to achieve other functions like inrush current limiting. Proper wiring and circuit design are crucial for optimal performance, leveraging configurations such as voltage dividers and operational amplifier circuits to interface with microcontrollers or other control systems.

Here are the key methods for incorporating NTC resistors into electronic circuits:

- Voltage Divider Configuration

The most common method involves creating a voltage divider with the NTC resistor and a fixed resistor. The output voltage is proportional to the NTC's resistance, which changes with temperature. This configuration is simple and effective for basic temperature sensing. The voltage output can be calculated using: V_out = V_in * R_ntc / (R_ntc + R_fixed), where V_in is input voltage, R_ntc is the NTC resistance and R_fixed is the fixed resistor resistance. - Operational Amplifier (Op-Amp) Circuits

For higher precision and signal conditioning, op-amps are used. An NTC can be part of the feedback loop, or used in conjunction with other components to generate a signal that is directly proportional to temperature changes. Op-amp circuits can also provide current output instead of voltage output if the design requires that, which is an advantage when using analog input devices with limited input impedance. - Direct Microcontroller Interface

NTC resistors can be directly connected to a microcontroller's Analog-to-Digital Converter (ADC) input pin, often as part of a voltage divider circuit. The microcontroller then converts the analog voltage value to a digital one, which is used for calculating the temperature using a look-up table or the Steinhart-Hart equation.

When integrating NTC resistors into circuits, consider these key points:

- Wiring Guidelines

Use appropriate gauge wires to ensure minimal resistance and accurate readings. Keep connections secure and consider using shielded cables in noisy environments to reduce signal interference. Minimize the wire length to the measurement point to minimize wire resistance which is in series with the thermistor. - Component Selection

Choose a fixed resistor with a tolerance suitable for your accuracy requirements and resistance value. Select an NTC with an appropriate base resistance and B-value to match the temperature range you are interested in, and which is matched to the requirements of the microcontroller's ADC input range. - Calibration and Linearization

Since NTC resistor behavior is non-linear, consider using a look-up table or the Steinhart-Hart equation for accurate temperature readings. Calibration is needed for high accuracy measurement. Calibration requires comparison to a standard instrument that is traceable to a recognized national standard.

Example circuit diagram: Voltage divider circuit with NTC and microcontroller ADC input:

NTC Resistor Datasheet Analysis: Reading and Understanding Specifications

A thorough understanding of an NTC thermistor's datasheet is crucial for selecting the appropriate component for a given application. Datasheets provide critical performance characteristics, enabling engineers to predict the behavior of the NTC thermistor within a circuit.

Key specifications to analyze include:

- Rated Resistance (R₂₅):

This is the resistance value at a standard reference temperature, typically 25°C. It's a fundamental parameter for circuit design and initial calculations. - B-value (B25/50 or similar):

The B-value, often specified as B25/50 or B25/85, quantifies the material's sensitivity to temperature changes, reflecting the relationship between resistance and temperature within a specific range. A higher B-value indicates a greater change in resistance for a given temperature variation. - Operating Temperature Range:

This specifies the temperature limits within which the NTC thermistor can be used safely and within its performance specifications. Exceeding these limits can lead to irreversible damage or inaccurate readings. - Tolerance:

Tolerance defines the acceptable deviation from the nominal resistance value at 25°C. This is usually expressed as a percentage and is critical for applications where precise resistance values are needed. A tighter tolerance provides better consistency between components. - Dissipation Constant:

The dissipation constant (δ) quantifies the power required to raise the thermistor's temperature by 1°C above the ambient. This parameter helps prevent self-heating effects, which can alter the accuracy of temperature measurements. - Thermal Time Constant:

This parameter indicates how quickly the thermistor responds to changes in temperature. It is the time required for the sensor to reach 63.2% of a new temperature value when exposed to a step change in the surrounding temperature. - Maximum Power Rating:

Specifies the maximum power the thermistor can handle without being damaged, which can cause the sensor to self-heat, changing its performance, and is critical for preventing thermal runaway.

Understanding the datasheet specifications enables design engineers to:

- Select the appropriate NTC thermistor for a given operating temperature range.

Ensuring the component operates safely and accurately. - Design temperature compensation circuits.

By using the resistance-temperature characteristics of the NTC thermistor. - Predict the accuracy of temperature measurements.

Considering the tolerance and B-value of the NTC thermistor. - Avoid self-heating effects.

By staying within the dissipation constant parameters.

Frequently Asked Questions About NTC Resistors

This section addresses common questions and concerns regarding NTC resistors, providing clarity on their limitations, accuracy, typical failure modes, and best practices for their effective use. By understanding these aspects, users can make informed decisions about incorporating NTC resistors into their designs.

- What are the primary limitations of NTC resistors?

NTC resistors exhibit a non-linear relationship between temperature and resistance, making precise temperature measurement complex without calibration or linearization circuits. They also have a limited operating temperature range, susceptibility to self-heating, and potential drift in resistance over time. Furthermore, they are generally not suitable for very high-temperature applications. - How accurate are NTC resistor-based temperature measurements?

The accuracy of temperature readings using NTC resistors depends on several factors, including the resistor's tolerance, the accuracy of the measurement circuitry, and the calibration process. While NTC resistors can provide relatively accurate temperature measurements when properly calibrated and compensated, they are not as inherently accurate as more precise temperature sensors like RTDs or thermocouples. - What are the typical failure modes of NTC resistors?

NTC resistors can fail due to a number of causes. Overheating, often caused by excessive current, can lead to permanent resistance changes or physical damage. Exposure to extreme temperatures outside of their specified operating range can also degrade performance. Physical damage, such as cracking or breaking due to stress, can also lead to failures. Additionally, prolonged exposure to moisture or corrosive substances can cause degradation or premature failure. - How can the non-linear behavior of NTC resistors be addressed in circuits?

The non-linear relationship between resistance and temperature in NTC resistors can be addressed using various linearization techniques in the measurement circuit. These methods include using look-up tables in microcontrollers, employing operational amplifier circuits with specific feedback networks, or through software algorithms that use polynomial equations or curve-fitting techniques to correct the non-linearity. These compensation methods enhance measurement precision. - Can NTC resistors be used for high-temperature applications?

NTC resistors are not typically suited for very high-temperature applications. Most standard NTC resistors have a maximum operating temperature limit of around 125-150°C. While there are some specialty NTC thermistors that can operate at slightly higher temperatures, they are not generally used for temperatures beyond 200-300°C. For high-temperature applications, thermocouples or RTDs (Resistance Temperature Detectors) are more suitable options. - How is the B-constant used in NTC resistor calculations?

The B-constant (also known as the material constant or beta value) is a parameter that characterizes the sensitivity of an NTC resistor to temperature change. It appears in the Steinhart-Hart equation which relates the NTC resistor’s resistance and temperature. This constant is a crucial factor in determining the temperature from the resistance of the thermistor and is specific to the material from which the NTC resistor is made. A higher B-constant indicates a more sensitive NTC thermistor with more pronounced changes in resistance for a given temperature change. - How do you select the best NTC resistor for a given application?

Choosing the right NTC resistor involves considering the required base resistance at a specific temperature (typically 25°C), the operating temperature range, and the desired B-constant to obtain the necessary sensitivity. The physical size and mounting requirements, along with the resistor's tolerance and cost, should also be taken into account. Analyzing the specific needs of the circuit and comparing them to the datasheet specifications is key to a proper selection.

NTC resistors are essential components that perform critical temperature-related functions across many industries, showcasing their significance in modern technology. Understanding how NTC resistors work, their different types, and selection criteria allows for their effective use in various temperature sensing and control applications. As technology evolves, the relevance and versatile application of the NTC resistor will undoubtedly expand, continuing to play a crucial role in thermal management and measurement.

AnyPCBA

AnyPCBA