Understanding Potentiometers: Types, Uses, and How They Work

Potentiometers, those small but mighty components found in everything from vintage radios to modern gaming controllers, are essential elements in electronics. They're not just simple on/off switches; potentiometers allow for smooth, continuous adjustment of electrical resistance. This makes them indispensable in controlling audio volume, adjusting motor speeds, and even calibrating sensitive equipment. This article dives deep into the world of potentiometers, exploring their various types, working principles, and the diverse applications that make them so crucial in our technological world.

What is a Potentiometer?

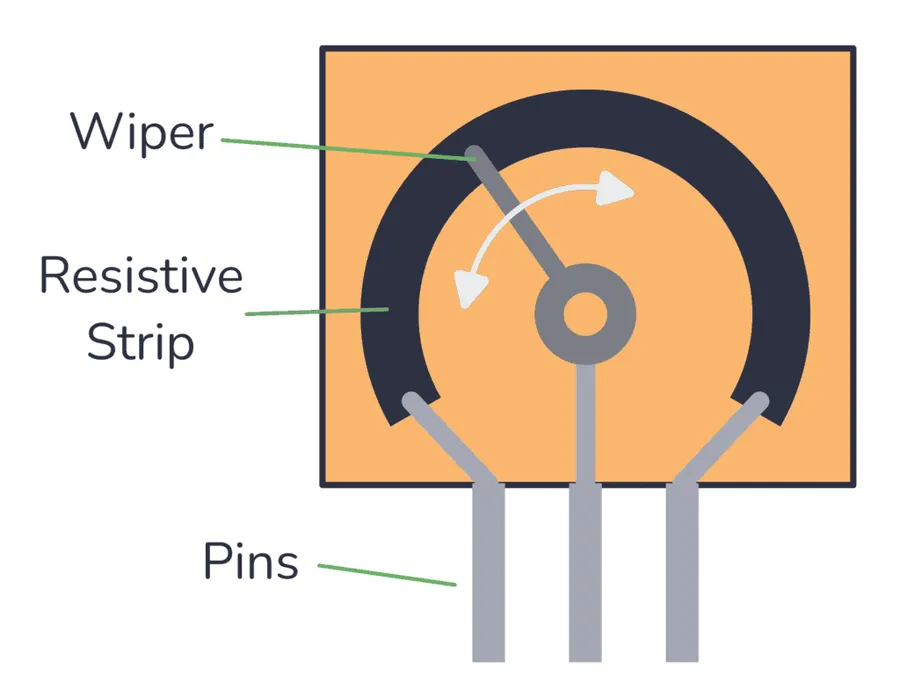

A potentiometer is a three-terminal electromechanical device functioning as a variable resistor, enabling manual adjustment of electrical resistance within a circuit. This adjustment is achieved by changing the position of a sliding contact, known as the wiper, along a resistive element. The fundamental components of a potentiometer include the resistive track, the wiper, and the terminals.

Potentiometers are crucial in a vast array of electronic applications where the capability to vary resistance is paramount. The relationship between the wiper position and resistance output can be linear or logarithmic, enabling diverse functionalities from simple volume control to precision adjustments in industrial equipment.

The precise design and construction of a potentiometer determine its physical size, maximum resistance value, power-handling capacity, and overall reliability. The choice of materials for the resistive element influences the precision and temperature stability of the potentiometer. Therefore, understanding the basic construction and function is critical for specifying the correct component for a given application.

How Potentiometers Work: The Core Principle

Potentiometers function by manipulating electrical resistance via a mechanical wiper that moves along a resistive track. This action allows for precise control over the division of voltage and the flow of current in a circuit. The fundamental principle relies on Ohm's Law, where resistance variation dictates the relationship between voltage and current.

At its core, a potentiometer includes three key elements: the resistive element, the wiper, and the terminals. The resistive element, typically a track of carbon composition or wire, offers a defined resistance. The wiper, a conductive contact, moves along this track. The terminals provide access to the electrical circuit.

The movement of the wiper divides the resistive element into two distinct sections. The resistance between one end terminal and the wiper changes according to the wiper's position. This change alters the voltage drop across this section, thereby controlling the flow of current. The total resistance between the two ends of the resistive element remains constant. This mechanism enables the potentiometer to function as a variable voltage divider, useful in various electronic applications.

| Component | Function |

|---|---|

| Resistive Element | Provides the track of fixed resistance |

| Wiper | Conductive contact that moves along the resistive element |

| Terminals | Connection points for integrating into a circuit |

Potentiometers come in two primary mechanical configurations: linear and rotary. Linear potentiometers feature a straight resistive track, and the wiper moves along this track linearly. Rotary potentiometers, in contrast, have a circular resistive track, and the wiper rotates around the center axis. Both types are fundamentally based on the same principle of variable resistance but they achieve resistance change through different modes of mechanical motion.

Types of Potentiometers: Rotary vs. Linear

Potentiometers are broadly classified into two main categories based on their mechanical operation: rotary potentiometers and linear potentiometers. This distinction influences their design, application, and suitability for various control tasks. Understanding these differences is crucial for selecting the correct potentiometer for a specific application.

| Feature | Rotary Potentiometer | Linear Potentiometer |

|---|---|---|

| Motion | Rotational motion of the wiper around a central axis | Linear motion of the wiper along a straight path |

| Design | Circular resistive element; wiper rotates via a shaft or knob | Straight resistive element; wiper slides along the length |

| Typical Applications | Volume controls, audio mixing, position sensing in rotating mechanisms | Slider controls, linear displacement sensing, instrument calibration |

| Advantages | Compact for rotational adjustments, intuitive interface for volume/tuning, robust and widely available | Precise linear control, direct representation of the controlled parameter's position, good for haptic feedback |

| Disadvantages | Less intuitive for linear adjustments, can be less precise in linear position sensing | Bulky for some applications, may require a longer space for full range of motion |

Key Potentiometer Specifications

Understanding the specifications of a potentiometer is crucial for selecting the correct component for a given application. These specifications dictate how the potentiometer will perform within a circuit and its suitability for different operating conditions. The primary specifications include resistance value, tolerance, power rating, and taper. These parameters determine the potentiometer's ability to control voltage and current in a circuit, its accuracy, and its durability.

| Specification | Description | Impact on Application |

|---|---|---|

| Resistance Value | The total resistance between the two end terminals of the potentiometer, measured in ohms (Ω). | Determines the range of resistance adjustment and the resulting voltage/current control. |

| Tolerance | The allowable deviation of the actual resistance from its nominal value, expressed as a percentage (e.g., ±10%). | Indicates the precision of the potentiometer's resistance; a lower tolerance means higher accuracy. |

| Power Rating | The maximum power the potentiometer can safely dissipate without damage, measured in watts (W). | Limits the amount of current that can flow through the potentiometer; exceeding the rating can lead to failure. |

| Taper | Describes the relationship between wiper position and the resistance, typically linear or logarithmic. | Affects how the resistance changes as the wiper is moved; linear tapers provide uniform change, logarithmic tapers change at different rates (often used for audio). |

The selection of these parameters is application-specific. For instance, a fine-tuning application would require a low-tolerance potentiometer, while a high-power circuit requires a potentiometer with a higher power rating. Understanding these specifications ensures the potentiometer will function effectively and reliably within the intended design parameters.

Potentiometer Applications in Audio Equipment

Potentiometers are indispensable components in audio equipment, providing the user with the ability to dynamically adjust signal levels and tonal characteristics. Their primary function is to act as variable voltage dividers, allowing for precise control over audio signals, ultimately influencing the listening experience. In audio systems, potentiometers are primarily used for functions such as volume control, tone adjustment (bass, treble, midrange), and balance.

- Volume Control

Potentiometers are used as the main element in volume control circuits, they act to vary the amplitude of the audio signal. Typically a logarithmic taper is used, because this matches human auditory perception in which loudness is not percieved linearly. The logarithmic taper ensures a more gradual and natural change in volume as the knob is turned. For example a 10 kΩ pot may be used. - Tone Adjustment

In tone control circuits, potentiometers are used to adjust the frequency response of the audio. This includes adjusting the amount of bass, treble, and midrange frequencies present in the signal. These pots act as part of a filter circuit, which changes its behavior depending on the potentiometer's position. For example a dual gang 50 kΩ pot may be used in this type of circuit. - Balance Control

In stereo audio systems, potentiometers are used to adjust the balance between the left and right audio channels. This allows the user to position the sound image to different extents between the left and right speaker.

| Application | Potentiometer Type | Taper Type | Typical Resistance Range |

|---|---|---|---|

| Volume Control | Rotary | Logarithmic | 5 kΩ to 100 kΩ |

| Tone Adjustment (Bass/Treble) | Rotary | Linear | 10 kΩ to 100 kΩ |

| Balance Control | Rotary | Linear | 10 kΩ to 100 kΩ |

Potentiometer Uses Beyond Audio: Industrial and More

While commonly associated with audio equipment, potentiometers are indispensable components in a wide array of non-audio applications, showcasing their versatility as variable resistors. Their ability to precisely control voltage and current makes them critical in industrial control systems, robotics, and instrumentation. This section delves into these diverse applications, highlighting their role in various technologies.

- Industrial Control Systems

Potentiometers are used for manual control of industrial processes, such as setting the speed of conveyor belts, adjusting the temperature in heating systems, or controlling the flow rate of liquids and gases. Their robustness and reliability make them suitable for harsh industrial environments. - Robotics

In robotics, potentiometers provide position feedback for robotic arms and joints. They serve as position sensors, allowing for precise movement and control, essential for tasks requiring accurate positioning. - Instrumentation

Potentiometers are essential in various measuring instruments such as multimeters, oscilloscopes and signal generators. They are crucial for calibration, range selection, and fine-tuning. - Motor Speed Control

Potentiometers act as rheostats, changing the motor speed by varying the amount of current delivered to the motor, offering a simple and reliable way to control motor driven devices. - Medical Equipment

Potentiometers are employed in various medical devices, including patient monitoring equipment and laboratory instruments, for precise adjustments and calibration. - Lighting Control

Potentiometers can be used to adjust the intensity of lighting systems, from simple dimmer switches in homes to sophisticated lighting controls in industrial settings.

| Application | Role of Potentiometer | Specific Examples |

|---|---|---|

| Industrial Control Systems | Manual process control | Speed control of conveyor belts, temperature adjustment, flow rate control |

| Robotics | Position feedback and control | Robotic arm joint positioning, servomotor control |

| Instrumentation | Calibration, range selection | Multimeters, signal generators, oscilloscopes |

| Motor Speed Control | Varying current to motor | Adjusting the speed of a conveyor belt motor or a small fan motor |

| Medical Equipment | Precise adjustments and calibration | Patient monitoring equipment and laboratory instruments |

| Lighting Control | Adjusting light intensity | Dimmer switches, stage lighting controls, industrial lighting adjustment |

Choosing the Right Potentiometer

Selecting the appropriate potentiometer for a given application requires careful consideration of several key factors. This ensures optimal performance, longevity, and compatibility within the intended circuit.

Here's a detailed guide to help in this selection process:

- Resistance Range

The total resistance value of the potentiometer should align with the intended circuit's requirements. It's crucial to choose a resistance range that covers the necessary adjustments without being unnecessarily high or low. - Taper (Linear vs. Logarithmic)

The taper describes how the resistance changes as the wiper moves. Linear taper potentiometers offer a uniform change in resistance, while logarithmic (audio) tapers provide a change more aligned with human perception, making them suitable for audio volume controls. - Power Rating

The potentiometer's power rating (measured in watts) must be adequate for the current and voltage levels in the circuit. Exceeding the rated power can lead to component failure and potential circuit damage. Always select a power rating that provides a safety margin above the expected operational power. - Size and Form Factor

The physical dimensions of the potentiometer must match the space constraints of the application. Whether it's a panel-mount, PCB-mount, or surface-mount component, its physical size should not hinder installation or operation. - Operating Conditions

Consider the environment in which the potentiometer will operate. Temperature, humidity, and exposure to other elements can affect its performance and lifespan. Certain applications may require sealed, more durable components. - Materials and Durability

The materials used in a potentiometer's construction directly influence its durability and reliability. Consider factors like the type of resistive element (carbon, cermet, wirewound), wiper material (gold-plated, metal), and the housing material to ensure long term performance in your application. - Adjustment Type

Potentiometers come in various adjustment types, including rotary (knob or shaft), slide (linear), and trimmers (preset). The most appropriate type depends on whether user accessibility or precise calibration is the primary concern. Consider the mechanism, ease of use, and precision when selecting the adjustment style

Frequently Asked Questions About Potentiometers

This section addresses common inquiries regarding potentiometers, offering clear and concise answers to enhance understanding of these versatile electronic components.

- What are potentiometers primarily used for?

Potentiometers are primarily used as adjustable voltage dividers or variable resistors in electronic circuits. This functionality enables them to control voltage levels, adjust signal strength (e.g., volume), and perform calibration adjustments in various applications. The core function involves manually adjusting a position that affects the output voltage or current in a circuit. - What are the two main types of potentiometers and what is the key difference between them?

The two main types of potentiometers are rotary and linear. Rotary potentiometers utilize a rotating shaft or knob to adjust the wiper position, commonly used in volume controls and rotational position sensing. Linear potentiometers use a sliding mechanism, ideal for applications requiring straight-line adjustments or position detection like faders in audio mixing boards or displacement sensors. The key difference lies in their actuation mechanism and how the wiper is moved to vary resistance. - How can I explain the working principle of a potentiometer in a simple way?

Imagine a strip of resistive material with three connection points (terminals). When a voltage is applied across the two fixed terminals, a consistent electrical field is established. A wiper (a sliding or rotating contact) makes contact with the resistive material. The position of the wiper effectively divides the resistive element. By adjusting the wiper's location, the proportion of the resistance seen by an output circuit changes, thus changing the voltage between the wiper and one of the fixed terminals. The position corresponds to a different resistance, and therefore, a different output voltage level. - What is the fundamental operating principle of a potentiometer?

The fundamental operating principle of a potentiometer relies on Ohm's law and the concept of voltage division. A potentiometer acts as a variable voltage divider, where the position of the wiper determines the proportion of the input voltage that appears at the output. By moving the wiper across the resistive track, the ratio of the resistance between the wiper and the two ends of the track changes, consequently altering the output voltage. This principle enables precise voltage and current control. - Can potentiometers be used as rheostats?

Yes, potentiometers can be used as rheostats (variable resistors) by connecting only two terminals—one fixed terminal and the wiper. In this configuration, the resistance between the wiper and the selected fixed terminal can be varied. This is useful in applications where current control, rather than voltage division, is required, such as in basic light dimming circuits. - What does a potentiometer's taper, or resistance curve, mean?

A potentiometer's taper defines how resistance changes with the wiper's physical position. Linear taper potentiometers show a consistent change in resistance for every degree of rotation (or millimeter of displacement), which is suitable for linear adjustments. Logarithmic taper (audio taper) potentiometers have a logarithmic curve, often used for volume controls since they better reflect human perception of loudness which is not linear. - How do I select the correct potentiometer resistance value for an application?

Selecting the right resistance value depends on your specific circuit needs. It should not be too low to cause excessive current flow or too high to impede the circuit's operation. Generally, potentiometer resistance values should be compatible with the load resistance and the supply voltage in your circuit, balancing the need for current draw, accuracy and control range. Typically, a potentiometer's resistance is chosen to be in the same order of magnitude as the load being controlled.

Troubleshooting Common Potentiometer Issues

Potentiometers, while generally reliable, can exhibit issues that affect their performance. Diagnosing and addressing these problems ensures continued accuracy and functionality within the intended application. This section focuses on common issues, their causes, and practical solutions, including replacement procedures.

- Noisy or Erratic Resistance

This is often caused by wear and tear on the resistive element or the wiper. Dust, corrosion, or physical damage can also contribute. Check for loose connections, debris, or visible damage. - Intermittent Signal

Intermittent signal issues may arise from a broken wiper arm, a dirty or corroded contact surface, or a faulty connection to the circuit. Test the potentiometer at various wiper positions and check connections. - Inconsistent Resistance Readings

Inconsistent readings can stem from a worn resistive track, resulting in unreliable voltage or current control. Carefully examine the resistive element for defects or wear. It can also be caused by incorrect wiring or poor solder joints. - Complete Failure (Open or Short Circuit)

A completely failed potentiometer presents either a short circuit or an open circuit. This can indicate damage to the internal components, terminals, or the wiper. Examine the potentiometer for any signs of physical damage or overheating. Use a multimeter to verify if the device has continuity, resistance, or a dead short. - Shaft Issues (Sticky or Loose)

A sticky or loose shaft can affect the user experience and accuracy. A worn or bent shaft can cause binding or imprecise adjustments. Carefully examine the shaft and the rotational mechanism for damage and wear, and lubricate or replace as needed.

When troubleshooting, use a digital multimeter to measure the resistance between the potentiometer's terminals. It can indicate if the resistance values match the manufacturer's specifications. Always disconnect the circuit power before testing or working on components.

If a potentiometer is found to be faulty, replacement is often the most effective solution. When selecting a replacement, ensure it matches the original specifications including resistance value, taper, and physical dimensions.

Potentiometers, as we’ve explored, are versatile and essential components in countless electronic systems. Their ability to provide smooth, variable resistance adjustment allows us to control devices with precision and ease. From the delicate volume controls of a vintage radio to the robust speed regulators in industrial machinery, potentiometers play a critical role. Understanding their types, functions, and specifications will help anyone choose the best components for their projects. As technology advances, potentiometers will continue to be a valuable tool in the development of new and innovative applications, solidifying their position as a cornerstone of electronic engineering.

AnyPCBA

AnyPCBA