Understanding the 104 Ceramic Capacitor: Specs, Uses, and More

In the intricate world of electronics, the 104 ceramic capacitor is a ubiquitous component. Like a tiny energy reservoir, this small but vital part plays a crucial role in countless devices. From smoothing power supply voltages to shaping circuit behavior, the 104 ceramic capacitor, with its 0.1uF capacitance, is an essential piece of the electronic puzzle. This article will delve deep into the world of this component, covering its specifications, applications, and practical considerations for anyone working with electronics. Let's unpack the secrets of the 104 ceramic capacitor and see why this component is so popular.

Decoding the 104 Code: Understanding Capacitance Values

The '104' marking on a ceramic capacitor is a standardized code indicating its capacitance value. This code, not arbitrary, is essential for selecting the correct capacitor for electronic circuit design. It specifies a capacitance of 100,000 picofarads (pF), which translates to 0.1 microfarads (µF) or 100 nanofarads (nF), thus a 104 ceramic capacitor is rated at 0.1 microfarads.

| Unit | Value |

|---|---|

| Picofarads (pF) | 100,000 pF |

| Microfarads (µF) | 0.1 µF |

| Nanofarads (nF) | 100 nF |

Key Specifications of a 104 Ceramic Capacitor

Beyond its capacitance value, a 104 ceramic capacitor is characterized by several critical specifications that directly influence its performance in electronic circuits. These specifications include voltage rating, tolerance, temperature coefficient, and dielectric material properties. Understanding these parameters is crucial for selecting the appropriate capacitor for a given application, ensuring circuit reliability and longevity.

| Specification | Typical Value | Description | Impact on Performance |

|---|---|---|---|

| Capacitance | 0.1 µF (100 nF) | The stored charge per unit voltage. | Determines the capacitor's ability to store electrical energy. |

| Voltage Rating | 50V (common, varies) | The maximum DC voltage that can be safely applied without risking dielectric breakdown. | Exceeding the rated voltage can lead to capacitor failure. |

| Tolerance | -20%/+80% (common) | The allowable deviation from the nominal capacitance value. | Affects the precision of timing and filtering circuits. |

| Temperature Coefficient | Varies by dielectric type (e.g., X7R, C0G) | The change in capacitance per unit change in temperature. | Determines the capacitance stability across varying temperatures. |

| Dielectric Material | Various (e.g., X7R, Y5V, C0G) | The insulating material between the capacitor's electrodes. | Influences temperature stability, voltage dependence, and aging. |

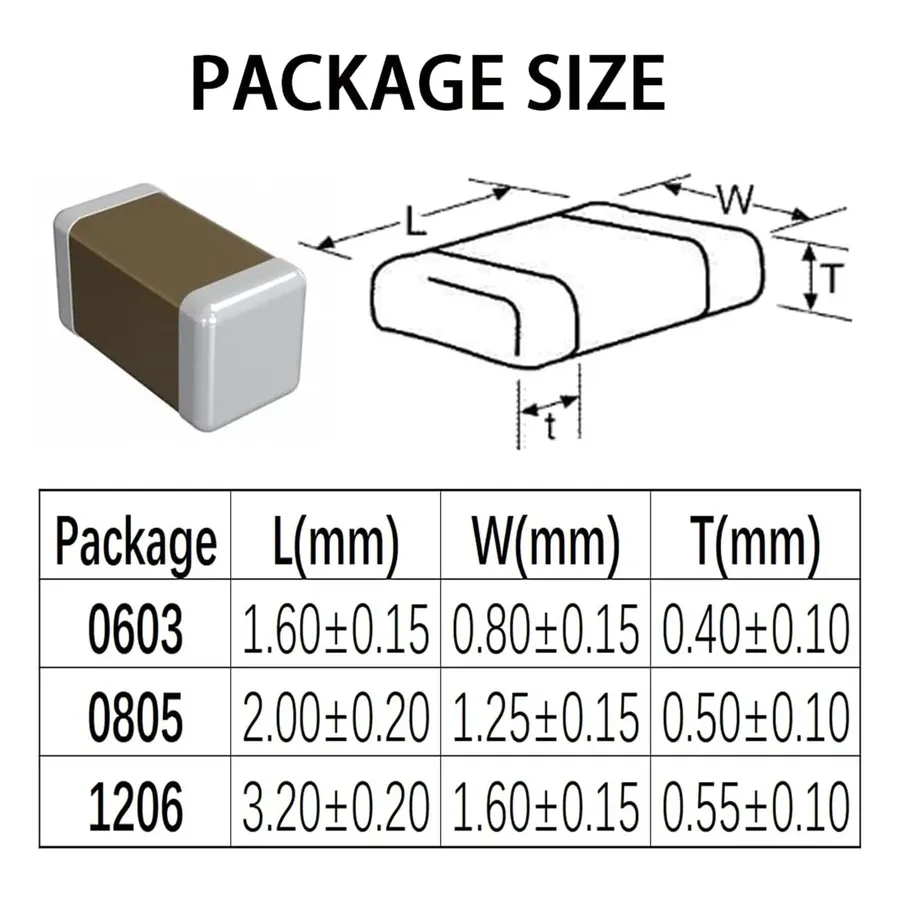

| Case Size | Varies (e.g., 0603, 0805) | The physical dimensions of the capacitor. | Affects the capacitor's mounting and compatibility with circuit board layout. |

It is imperative to note that the voltage rating is a critical parameter. Applying a voltage exceeding the capacitor's rating can cause dielectric breakdown, leading to short circuits or permanent damage. Furthermore, a wide tolerance range indicates that the actual capacitance value may vary significantly from the nominal 0.1uF, which can affect circuit performance, especially in precision applications. Temperature coefficient and dielectric material choice also play a vital role, impacting the stability and reliability of the capacitor under diverse operating conditions. Therefore, designers must carefully consider these specifications when selecting a 104 ceramic capacitor.

104 Ceramic Capacitor vs. Monolithic Capacitors

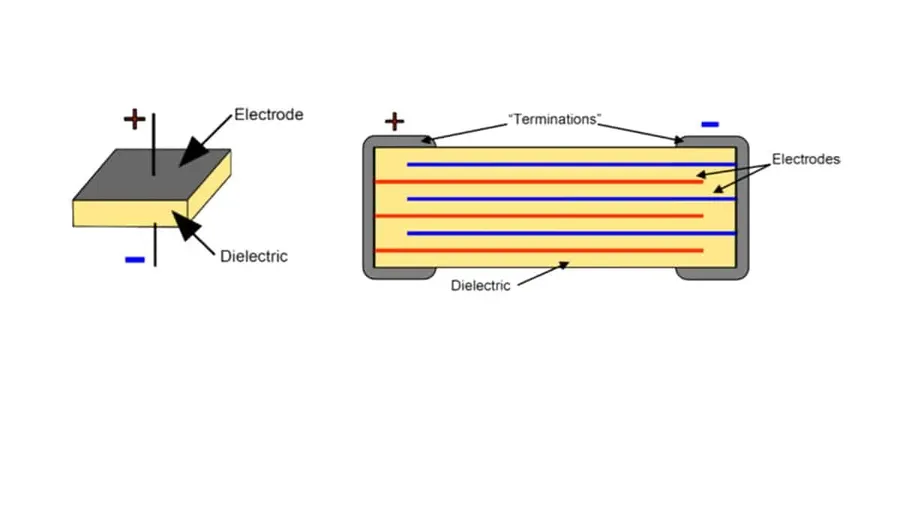

While the term 'monolithic capacitor' can sometimes encompass ceramic capacitors, it generally refers to multilayer ceramic capacitors (MLCCs) that are constructed with a specific internal structure. A 104 ceramic capacitor is usually a type of MLCC. This section focuses on differentiating the construction, applications and advantages of various monolithic capacitors including the 104.

| Feature | 104 Ceramic Capacitor (MLCC) | Other Monolithic Capacitors |

|---|---|---|

| Construction | Multiple layers of ceramic dielectric interleaved with metal electrodes, often with a barium titanate dielectric, resulting in a small size. | Similar layered construction with different dielectric materials such as polymers, tantalum or other ceramics, often resulting in different electrical and physical properties. |

| Capacitance Range | Typically in the range of picofarads to a few microfarads, with the 104 (100nF or 0.1uF) being a common value. | Wider range from picofarads to hundreds of microfarads, depending on the dielectric and size. |

| Voltage Rating | Commonly available in ratings from a few volts to several kilovolts, with 50V being a typical value for the 104. | Varies widely, from a few volts for tantalum and polymer capacitors, to kilovolts for high-voltage ceramic capacitors. |

| Temperature Stability | Can vary, with some formulations exhibiting significant changes in capacitance over temperature. COG/NPO formulations offer very high stability. | Varies based on the dielectric. Tantalum and polymer capacitors have lower temperature coefficients than many ceramic types but often lower capacitance density. |

| ESR(Equivalent Series Resistance) | Generally low, especially for smaller sizes, which is beneficial for high-frequency applications. | Can vary widely, polymer and tantalum have low ESR, while ceramic capacitors may have slightly higher ESR. This needs to be considered in high-current applications. |

| Typical Applications | Decoupling, bypass, filtering, and timing circuits, where size is a major consideration. | Bulk capacitance, power rail decoupling, and applications with high current demands, depending on the type. |

| Advantages | Small size, low cost, good high-frequency performance, and readily available. | Wider capacitance range, better stability or higher voltage capabilities in some cases. |

| Disadvantages | Can be susceptible to mechanical stress and can sometimes be microphonic. Limited capacitance compared to other monolithic types. | Higher cost in many cases, lower frequency performance or larger size depending on the dielectric type. |

Common Applications of the 104 Ceramic Capacitor

The 104 ceramic capacitor, with its 0.1µF capacitance, finds widespread use across diverse electronic applications. Its combination of a useful capacitance value, compact size, and relative low cost makes it a staple in many circuits. This section explores typical applications as well as some of its less common uses.

- Power Supply Decoupling

A primary function of the 104 capacitor is to act as a decoupling capacitor. Placed close to integrated circuits, it provides a local energy reservoir and stabilizes the power supply by filtering out high-frequency noise and voltage spikes. This ensures stable operation of the powered device, preventing erratic behavior or damage. It is commonly used in digital circuits, microcontrollers, and other sensitive components. - Noise Filtering

The 104 capacitor is effective at filtering high-frequency noise in circuits. When a signal contains unwanted frequencies, the capacitor shunts these frequencies to ground, allowing only the desired signal to pass. This technique is often used in analog signal processing and audio circuits to improve signal quality. - Timing Circuits

While not typically used for precise timing, 104 capacitors can serve as timing components in less critical timing circuits, such as in astable multivibrators (oscillators) or in time-delay circuits, often in combination with resistors. They also serve as part of the RC filter network for signal conditioning. - Signal Coupling

In some low-frequency applications, a 104 capacitor can couple AC signals while blocking DC components, which are necessary to prevent DC bias from affecting sensitive parts of a circuit. The AC signal passes through, while the DC bias cannot. - Signal Bypassing

The 104 capacitor is used to bypass AC signals to ground in high frequency circuits, ensuring that these signals don't interfere with other parts of the system. This is particularly useful in RF circuits and when isolating sections of a more extensive system. - Less Common Applications

Less conventional uses include frequency compensation networks and specialized sensors, such as some capacitive proximity sensors where the specific capacitance of the 104 is leveraged for unique circuit operations.

Practical Considerations When Using 104 Ceramic Capacitors

While 104 ceramic capacitors are generally robust, proper handling and usage are crucial for optimal performance and longevity. This section outlines essential practical considerations, including polarity awareness, mounting techniques, and soldering practices to ensure these components function reliably in your circuits.

104 ceramic capacitors are non-polarized components, meaning they can be installed in a circuit in either direction. However, while polarity isn't a concern for typical applications, it's important to note that specific circuit designs might require careful consideration of parasitic effects based on the capacitor's orientation. For example, if a design is very sensitive to noise or electromagnetic interference, the orientation of the capacitor with respect to nearby components may affect performance.

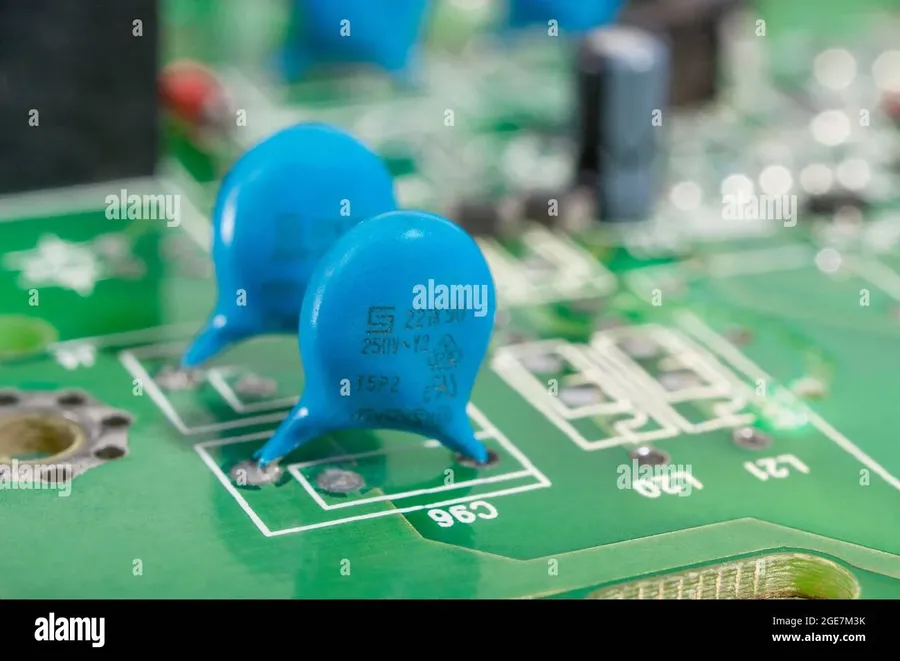

Mounting and soldering techniques are critical to ensure the integrity of the 104 ceramic capacitor. For surface mount components, using the correct solder paste and reflow profiles are essential to avoid cracking. For through-hole components, avoid excessive bending of leads, and ensure a good solder joint is created without overheating. These precautions prevent mechanical stress that can lead to internal damage or premature failure.

Proper soldering techniques are also crucial. Applying excessive heat or duration during soldering can lead to thermal shock, which may cause the capacitor's ceramic material to crack or change its electrical characteristics. The following best practices should be observed: Use a temperature-controlled soldering iron at the recommended temperature for your specific solder type. Avoid applying excessive pressure on the component and use enough solder to form a robust joint, but not so much that it over-fills the pad. Solder each capacitor within the maximum specified dwell time.

Testing and Troubleshooting 104 Ceramic Capacitors

Identifying a faulty 104 ceramic capacitor is crucial for circuit reliability. This section details the methods for testing these capacitors, primarily using a multimeter, to assess their capacitance and detect common failures like shorts or open circuits.

A 104 ceramic capacitor, with its nominal capacitance of 0.1uF, can degrade over time or fail due to various stresses. Proper testing ensures the capacitor functions as intended within the circuit.

- Visual Inspection

Before electrical testing, visually inspect the capacitor for physical damage, such as cracks, chips, or discoloration. A physically damaged capacitor is likely faulty and should be replaced. - Capacitance Measurement

Using a multimeter with capacitance measurement capability, measure the capacitor's value. A healthy 104 capacitor should measure close to 0.1uF (100nF). Deviations beyond the tolerance range (typically -20%/+80%) indicate a potential issue. Note: some multimeters measure in pF, the reading should be near 100,000pF - Short Circuit Test

Set the multimeter to the continuity or resistance testing mode. A short circuit is indicated by a very low resistance measurement near zero ohms or a continuity beep. A shorted capacitor should be immediately replaced. - Open Circuit Test

An open circuit is harder to diagnose directly with a multimeter resistance test. It usually shows a very high or infinite resistance (or no continuity). If capacitance measurement is zero, the capacitor is most likely open. An open capacitor should be immediately replaced.

| Test | Expected Result for a Functional 104 Capacitor | Indication of a Faulty Capacitor |

|---|---|---|

| Visual Inspection | No visible damage | Cracks, chips, discoloration |

| Capacitance Measurement | Approximately 0.1uF (100nF), within tolerance | Significant deviation from 0.1uF, outside of the tolerance range (typically -20% to +80%) |

| Short Circuit Test | High resistance (no continuity) | Very low resistance (near zero ohms) or continuity |

| Open Circuit Test | Non-Zero capacitance measurement | Zero capacitance measurement |

Frequently Asked Questions About 104 Ceramic Capacitors

This section addresses common inquiries regarding 104 ceramic capacitors, providing clarity on their specifications, usage, and comparison with similar components. Understanding these aspects is crucial for effective application in various electronic circuits.

- What is the typical voltage rating of a 104 ceramic capacitor?

While a common voltage rating for a 104 ceramic capacitor is 50V, it's crucial to consult the manufacturer's datasheet for the specific component you're using. Voltage ratings can vary, and exceeding the rated voltage can lead to component failure or damage to the circuit. - How do I correctly interpret the markings on a 104 ceramic capacitor?

The '104' marking indicates a capacitance value of 100,000 picofarads (pF), which is equivalent to 100 nanofarads (nF) or 0.1 microfarads (µF). The first two digits (10) are the significant figures, and the third digit (4) is the multiplier, representing 10^4. Thus, 10 x 10^4 pF = 100,000 pF. - How does a 104 capacitor compare to a 103 capacitor?

A 104 capacitor has a capacitance of 100nF or 0.1uF, while a 103 capacitor has a capacitance of 10nF or 0.01uF. The difference lies in their capacitance values; 104 provides ten times more capacitance than a 103 capacitor. Choosing between them depends on the specific capacitance requirements of the circuit. - When should I choose a 104 ceramic capacitor over other ceramic capacitors?

The choice depends on the required capacitance in your circuit. A 104 ceramic capacitor is selected when you specifically need 0.1µF capacitance. Consider factors like the application's frequency, voltage, and temperature requirements when making the selection. Smaller values (e.g., 102, 103) are often used for high-frequency decoupling, while larger values (e.g., 105, 106) are used for power filtering or energy storage. - Are 104 ceramic capacitors polarized?

No, 104 ceramic capacitors are generally non-polarized. This means they can be installed in a circuit without concern for orientation. However, in some specific circuit designs, especially those involving high-frequency applications or sensitive circuits, care must be taken regarding proper circuit design and layout to ensure stable and optimal performance. - How do I test a 104 ceramic capacitor to determine if it's faulty?

A multimeter with capacitance measurement capability is required for testing. You should measure the capacitance. If the measured value is significantly different from 0.1uF or shows either a short circuit (very low resistance) or an open circuit (very high resistance), the capacitor is likely faulty. Visual inspection for physical damage, like cracks or swelling, is also advised. - What is the tolerance range typically associated with a 104 ceramic capacitor?

The tolerance of a 104 ceramic capacitor indicates the permissible deviation from its nominal capacitance value. Commonly, the tolerance range is -20%/+80%. This means the actual capacitance could be as low as 0.08uF or as high as 0.18uF. For precision applications, capacitors with tighter tolerances may be necessary.

Where to Purchase Genuine 104 Ceramic Capacitors

Sourcing genuine 104 ceramic capacitors is crucial for reliable circuit performance. Counterfeit components can lead to unpredictable behavior and even system failures. This section provides guidance on identifying reputable sources to ensure you obtain authentic parts.

- Reputable Online Electronics Distributors

Major distributors like Digi-Key, Mouser Electronics, and Arrow Electronics are known for their extensive catalogs of genuine electronic components. These sources often provide detailed datasheets and specifications, along with traceability information, which is beneficial for verifying the authenticity of the 104 capacitors. They also offer bulk ordering options and fast shipping. - Manufacturer-Authorized Suppliers

Purchasing directly from the manufacturer or their authorized suppliers offers the highest level of assurance of authenticity. These channels can often be more expensive due to higher minimum order quantities and more formal business procedures, but they guarantee that components are genuine and meet quality standards. - Specialized Electronics Component Retailers

Smaller retailers specializing in electronic components can sometimes provide a good option, but it's crucial to verify their reputation and customer reviews. Look for retailers that offer detailed product information and transparent supply chains. It is best to go with recommendations from established communities when considering this option. - Avoiding Counterfeit Sources

Be extremely cautious when purchasing from less reputable online marketplaces and unauthorized resellers. These platforms are often frequented by sellers of counterfeit components. Always compare prices with major distributors and look for clear signs of authenticity, such as consistent markings, proper packaging, and manufacturer’s lot numbers. Consider performing tests to confirm the validity of the component, as there is no guarantee that components from such sources are genuine or meet specification - Tips for Purchasing Genuine Parts

1. Check for manufacturer's packaging and markings. 2. Look for consistency in labeling. 3. Cross-reference the part number with the official manufacturer datasheet. 4. Ask for traceability information. 5. If possible, obtain samples for testing before a bulk purchase. 6. Compare pricing against major distributor prices to avoid being caught out by excessively low prices. 7. Purchase a small number of components to test before ordering in bulk.

The 104 ceramic capacitor, with its 0.1uF capacitance, might be a tiny component, but it is crucial in the world of electronics. Its widespread use, versatility, and availability make it indispensable for countless applications. By understanding its specifications, applications, and best practices, you can harness the full potential of the 104 ceramic capacitor, driving your electronic projects with precision and reliability, and building better devices in your lab, your home or anywhere else electronics are needed. Keeping this in mind will help you effectively use the 104 ceramic capacitor.

AnyPCBA

AnyPCBA