Understanding the 200 Ohm Resistor: Applications, Types & More

In our digitally driven world, electronic components are the unsung heroes powering our everyday devices. A seemingly simple component like a 200 ohm resistor plays a pivotal role in regulating current flow and ensuring circuit stability. Just as a traffic light controls the flow of cars, a 200 ohm resistor manages the flow of electrons, preventing potential damage and allowing electronic devices to function as intended. This article will explore the various facets of the 200 ohm resistor, from its construction and types to its color coding and applications, providing a comprehensive understanding of this crucial electronic element.

What is a 200 Ohm Resistor?

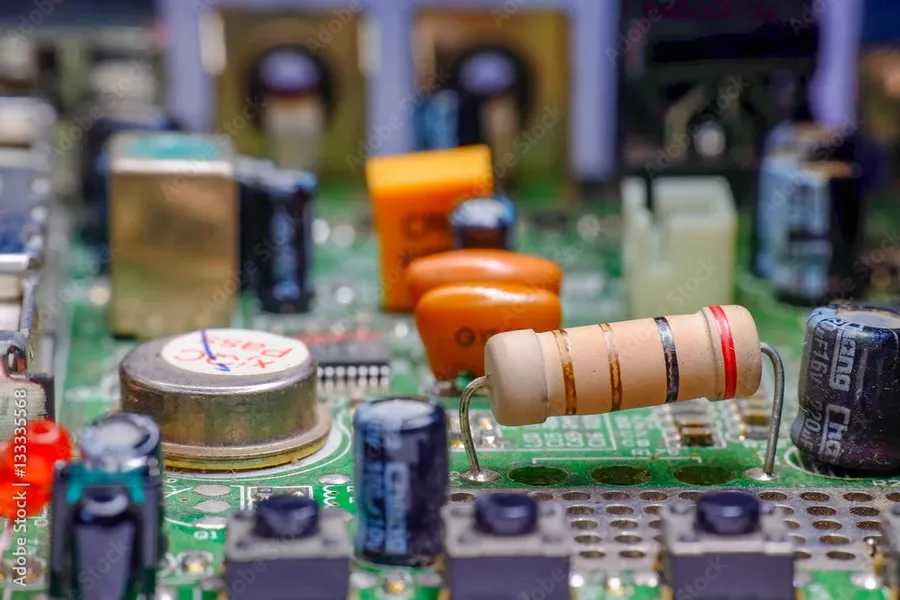

A 200 ohm resistor is a fundamental passive electronic component characterized by its specific resistance of 200 ohms. It plays a crucial role in electronic circuits by impeding the flow of electrical current, effectively controlling the current within a circuit, dividing voltages and setting gains. This essential component is found in nearly all electronic devices, forming the basis for many electronic functions.

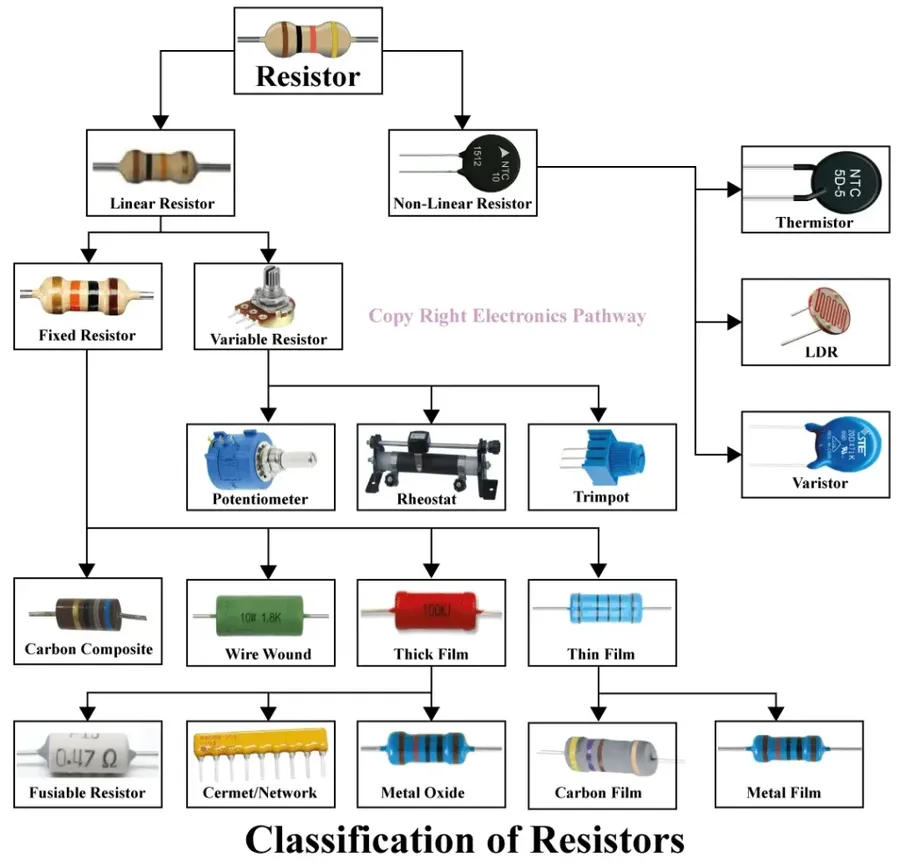

Types of 200 Ohm Resistors

200 ohm resistors are manufactured using different materials and construction techniques, leading to a variety of types each with distinct characteristics and applications. These variations impact performance in terms of precision, power handling, and stability under different operating conditions. Selecting the appropriate resistor type is crucial for optimal circuit function.

| Resistor Type | Construction | Tolerance | Power Rating | Temperature Coefficient | Typical Applications |

|---|---|---|---|---|---|

| Carbon Film | A thin carbon film deposited on an insulating substrate. | Typically 5%, but can be up to 20%. | Low (e.g., 1/8W - 1/2W) | High | General purpose applications, hobbyist projects. |

| Metal Film | Thin metal alloy film deposited on an insulating substrate. | Typically 1%, or lower (0.1% available). | Low (e.g., 1/8W - 1/2W) | Lower than carbon film | Precision circuits, low noise applications. |

| Wire-Wound | Wire is wound around an insulating core. | Typically 1% - 5%. | Medium to High (e.g., 1W - 50W+) | Very low | High-power applications, power supplies. |

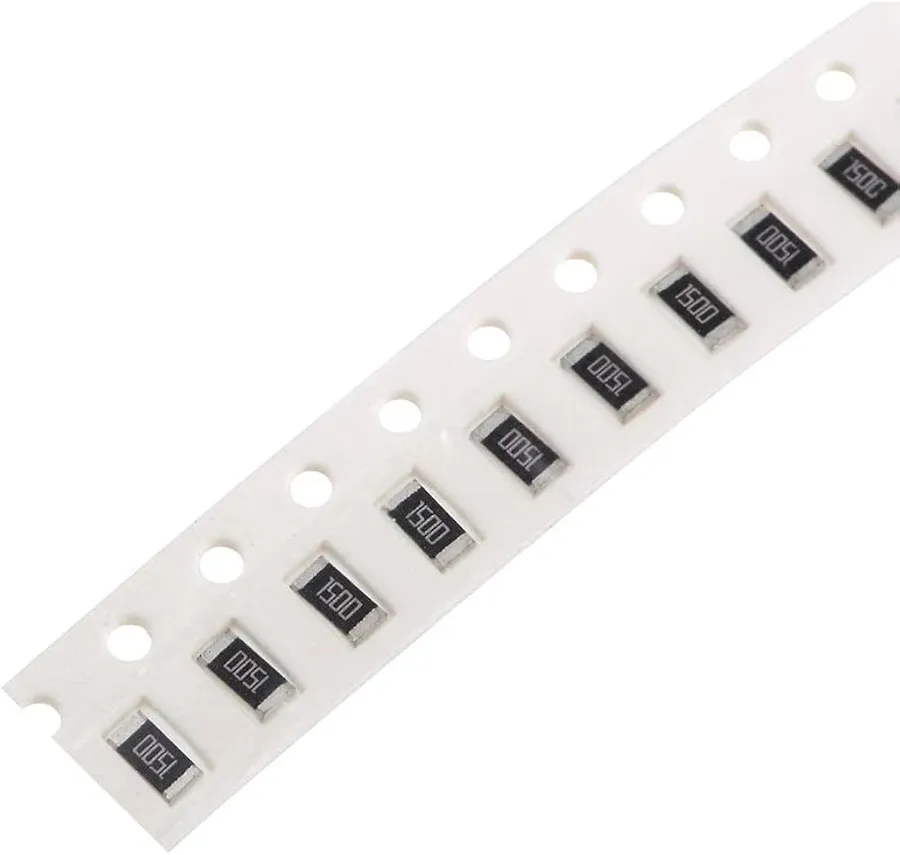

| Surface Mount (SMD) | Small, rectangular resistor with pads for direct surface mounting. | Typically 1% or 5%. | Low to medium (e.g., 1/16W - 1/2W) | Moderate | High-density circuit boards, miniaturized devices. |

200 Ohm Resistor Color Code

The color code on a 200 ohm resistor is a standardized method to quickly identify its resistance value and tolerance. Typically, for a 200 ohm resistor with 5% tolerance, the color bands are Red, Black, Brown, and Gold, respectively. Understanding this coding system is crucial for accurately selecting and using resistors in electronic circuits.

| Band Number | Color | Value | Multiplier |

|---|---|---|---|

| 1st Band | Red | 2 | |

| 2nd Band | Black | 0 | |

| 3rd Band | Brown | 10^1 | |

| 4th Band | Gold | 5% Tolerance |

The first two bands represent the significant digits of the resistance value, while the third band acts as a multiplier, and the fourth band represents the tolerance.

In the specific case of a 200 Ohm resistor: the Red band corresponds to '2', the Black band indicates '0', and the Brown band as a multiplier of 10^1 which equals 10, resulting in 20 x 10 = 200 ohms. The Gold band means 5% tolerance. Other color band combinations may exist for 200 ohm resistors with different tolerance ratings, but the three first bands will be similar.

Power Rating of a 200 Ohm Resistor

The power rating of a 200 ohm resistor is a critical specification that dictates the maximum amount of electrical power, measured in watts, the component can safely dissipate as heat without sustaining damage or altering its resistance. Selecting a resistor with an adequate power rating is crucial for preventing overheating, which can lead to premature failure, circuit malfunction, or even fire hazards. This rating is determined by the resistor's physical characteristics and materials, directly impacting its ability to manage thermal energy generated during operation.

| Power Rating (Watts) | Typical Package Size | Common Applications | Heat Dissipation Capability |

|---|---|---|---|

| 1/8W (0.125W) | Small through-hole or 0805 SMD | Low-power signal processing, small sensor circuits | Low |

| 1/4W (0.25W) | Standard through-hole or 1206 SMD | General purpose, LED current limiting, logic circuits | Moderate |

| 1/2W (0.5W) | Larger through-hole or 1206/1812 SMD | Audio circuits, moderate current draw applications | Moderate to High |

| 1W | Larger through-hole | Power circuits, higher current applications | High |

| 2W | Large through-hole | High current circuits, power supplies | High |

| 5W and Higher | Specialized large packages (e.g., heat sink mountable) | High power applications like motor control, power conversion | Very High |

Applications of the 200 Ohm Resistor

The 200 ohm resistor's versatility makes it a cornerstone in numerous electronic applications. Its primary function is to control current flow and voltage levels within circuits, enabling a range of operations from simple LED illumination to complex signal processing.

- LED Current Limiting

A 200 ohm resistor is frequently employed in series with LEDs (Light Emitting Diodes) to regulate the current passing through them. This prevents the LED from drawing excessive current, which can lead to premature failure or damage. The specific resistance value ensures the LED operates within its safe operating parameters, enhancing both lifespan and performance. - Voltage Dividers

In voltage divider configurations, the 200 ohm resistor is used in conjunction with other resistors to produce a specific output voltage, a fraction of the input voltage. This is essential in creating reference voltages, providing bias for transistors, and scaling down high voltages to levels suitable for sensitive circuits. The resistor values determine the precise voltage output, making accurate resistance vital. - Filtering Circuits

Resistors, including the 200 ohm variant, are vital components in filter circuits. Combined with capacitors or inductors, they help filter out unwanted frequencies from electronic signals. This is used in audio applications, power supplies, and communication systems, allowing specific frequencies to pass through while attenuating others, achieving cleaner and more reliable circuit operation. - Pull-up and Pull-down Resistors

In digital logic circuits, 200 ohm resistors can be employed as pull-up or pull-down resistors. These resistors establish a defined logic level (high or low) when an input is left floating or not actively driven. This ensures stable and consistent digital signaling, preventing unpredictable behavior caused by noise or undefined states. - Sensor Interfacing

Many sensors output analog signals that need to be converted to digital for processing. The 200 Ohm resistor can be part of the analog to digital conversion circuit, ensuring an accurate and stable reading by limiting the current flow between the sensor and the processing circuit.

Frequently Asked Questions About 200 Ohm Resistors

This section addresses common inquiries about 200 ohm resistors, providing concise answers to frequently asked questions to help clarify their use and selection in electronic circuits.

- What is the difference between a 200 ohm resistor and a 220 ohm resistor?

While both are standard resistor values, the 200 ohm resistor has a slightly lower resistance compared to the 220 ohm resistor. This means a 200 ohm resistor will allow a slightly higher current flow under the same voltage, and they are not interchangeable in all applications. The choice depends on the specific current or voltage requirements of the circuit. - What are the common color codes for a 200 ohm resistor?

For a standard 200 ohm resistor, the color bands are typically Red, Black, Brown, and Gold. The red band represents '2', the black band represents '0', the brown band is the multiplier, or '10 to the power of 1', and the gold band represents 5% tolerance. Note that variations can exist, particularly with older or less common resistor types. - What does the tolerance rating mean for a 200 ohm resistor?

The tolerance rating, often indicated by a gold or silver band, specifies the allowable deviation of the actual resistance value from the stated 200 ohms. A 5% tolerance (gold band) means the actual resistance may be between 190 ohms and 210 ohms. Lower tolerances result in more precise resistance values. - How do I choose the correct power rating for a 200 ohm resistor in my project?

The power rating of a resistor indicates how much power it can safely dissipate as heat. To select the correct power rating, calculate the power that the resistor will dissipate in your circuit using the formula P=I^2 * R or P=V^2/R, where P is power in Watts, I is current in Amps, V is voltage in Volts, and R is resistance in Ohms. Select a resistor with a power rating that exceeds the calculated power by a safe margin (typically 2x or greater) to avoid overheating. - Can a 200 ohm resistor be used in LED circuits?

Yes, a 200 ohm resistor is commonly used in LED circuits to limit current flow and prevent damage to the LED. The exact value will depend on the LED's forward voltage and current requirements. You will need to calculate the appropriate resistance to ensure the LED operates at its rated parameters. - What is the difference between a carbon film and a metal film 200 ohm resistor?

Metal film resistors are generally more precise and stable than carbon film resistors, meaning they have a tighter tolerance and less variance in their resistance as temperature changes. While carbon film resistors are more economical, metal film resistors are preferred in applications needing greater accuracy and reliability. - Where can I find a 200 ohm resistor?

200 ohm resistors are readily available from most electronics component retailers, both online and in physical stores. You can purchase individual resistors, or often, a kit of many different values, which includes 200 ohm resistors. Online marketplaces also offer competitive pricing and availability.

Selecting the Right 200 Ohm Resistor

Selecting the appropriate 200 ohm resistor for a given application requires a careful consideration of several key factors. These include the resistor's type, its power rating, its tolerance, and its physical packaging. Each of these elements plays a crucial role in the performance and reliability of the circuit.

- Resistor Type

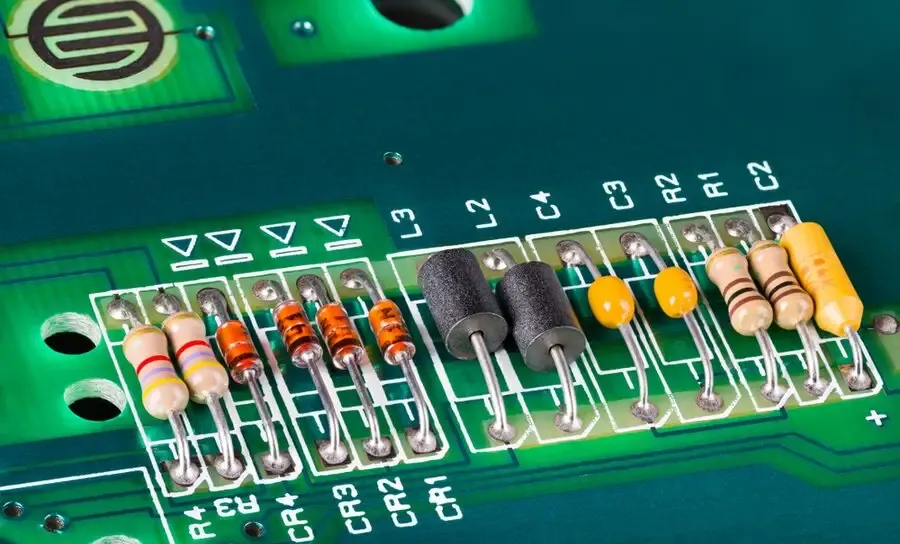

The choice between carbon film, metal film, wire-wound, or SMD resistors is paramount. Metal film resistors offer superior precision and temperature stability, making them ideal for critical applications. Wire-wound resistors, while bulky, are robust for high-power applications, whereas carbon film is cost-effective for general use, and SMDs are ideal for high-density designs. - Power Rating

The resistor's power rating, indicated in watts (W), must exceed the maximum power it is expected to dissipate during operation. Operating a resistor beyond its rating can lead to overheating and failure. Common power ratings for 200 ohm resistors include 1/8W, 1/4W, 1/2W, 1W, and 5W. Ensure a safety margin by choosing a resistor with a higher power rating than the calculated power dissipation. - Tolerance

The tolerance rating dictates the permissible deviation of the actual resistance from the nominal 200 ohms. Common tolerances include 5%, 1%, and 0.1%. For applications where precise resistance is critical, a resistor with a lower tolerance is essential. For instance, precision circuits might necessitate 0.1% resistors, while less stringent applications could use 5% tolerance resistors. - Packaging

The packaging refers to the physical form of the resistor and impacts its suitability for different installation methods. Through-hole resistors are used with breadboards and prototype circuits, while surface-mount devices (SMDs) are compact, efficient for high volume production, and are essential for printed circuit boards (PCBs). The packaging must align with the board and assembly requirements of the target application.

By carefully considering these factors, you can ensure that the 200 ohm resistor you choose will perform reliably and as intended within your project's specific requirements.

200 Ohm Resistor: Real World Examples

The 200 ohm resistor, while a seemingly simple component, plays a critical role in a vast array of everyday electronic devices. Its precise resistance allows it to perform essential functions like current limiting, voltage division, and signal conditioning, making it indispensable in modern technology.

- LED Lighting

In LED circuits, a 200 ohm resistor is commonly used in series with the LED to limit the current flowing through it. This prevents the LED from drawing excessive current which can cause premature failure. The resistor ensures the LED operates at its designed current, producing optimal light output and extending its lifespan. For example, many household LED bulbs utilize resistors in this way. - Audio Circuits

Many audio amplifiers and circuits use 200 ohm resistors in various stages. They are used for setting the gain of amplification stages and for impedance matching. For example, in headphone amplifiers and audio preamplifiers, a resistor of this value can be found in the signal path. This helps ensure proper signal levels and optimal performance. - Motor Control Circuits

Small DC motors often utilize 200 ohm resistors to control the speed or torque provided to the motor, especially where precise control is needed. They may be used in conjunction with other components like transistors or microcontrollers. For instance, in robotics and automation applications, resistors like these are essential for fine-tuning motor operation. - Sensor Interfacing

In many sensor applications, the output of the sensor might need some conditioning before being processed by a microcontroller or signal conditioning circuit. 200 ohm resistors can be used in these circuits to provide voltage division or impedance matching. For example in temperature sensors, or light sensors, a 200 ohm resistor may be part of the voltage divider circuit. - Microcontroller Circuits

Microcontrollers use a number of resistors in various circuits for tasks like pull-up or pull-down resistors for input pins, and for limiting current to connected components. The 200 ohm resistors is found in many of these roles, due to its balance between reasonable current flow and good impedance. They can also be used in conjunction with small signals to reduce the risk of damage to microcontroller inputs.

Comparing Different 200 Ohm Resistors: A Table

Selecting the appropriate 200 ohm resistor for a given application necessitates a thorough understanding of the distinctions between various types. The following table presents a comparative analysis, highlighting key characteristics such as material, tolerance, and power rating, aiding engineers and hobbyists in making informed component selections.

| Resistor Type | Material | Tolerance | Power Rating (Typical) | Temperature Coefficient | Typical Applications |

|---|---|---|---|---|---|

| Carbon Film | Carbon composition | ±5%, ±10% | 1/8W, 1/4W, 1/2W | High | General purpose, low-cost circuits |

| Metal Film | Nickel-chromium alloy | ±1%, ±0.5% | 1/8W, 1/4W, 1/2W, 1W | Low | Precision circuits, audio applications |

| Wire-Wound | Nichrome or similar resistance wire | ±1%, ±5% | 1W, 2W, 5W, 10W+ | Low | High-power applications, current sensing |

| SMD (Surface Mount) | Thick or thin film | ±1%, ±5% | 1/16W, 1/10W, 1/8W, 1/4W | Moderate | Compact circuits, automated assembly |

| Metal Oxide Film | Metal oxide | ±1%, ±2%, ±5% | 1/2W, 1W, 2W | Moderate | High voltage or high surge current applications |

The 200 ohm resistor, often overlooked, is a workhorse in the electronic world, silently ensuring that circuits function as intended. This component can be compared to a critical valve in a plumbing system, controlling the flow of electricity to prevent overload and facilitate the effective operation of electronic devices. Whether you are working with LEDs or other sensitive circuits, selecting the correct 200 ohm resistor is key to optimizing your project and preventing damage. By gaining a better understanding of its types, power ratings, color coding and applications, you'll be able to make better decisions and build more robust and reliable electronics projects.

AnyPCBA

AnyPCBA