Unleashing the Power of Large Capacitors: A Comprehensive Guide

From the smartphones in our pockets to the massive power grids that light our cities, capacitors play a critical role in modern electronics. Among these, large capacitors stand out for their ability to store significant amounts of electrical energy, enabling various essential functions. In this article, we will delve into the world of large capacitors, exploring their unique characteristics, diverse applications, and key considerations for their effective use. We'll uncover the 'big' impact of these humble components and clarify their importance in the realm of technology.

What is a Large Capacitor?

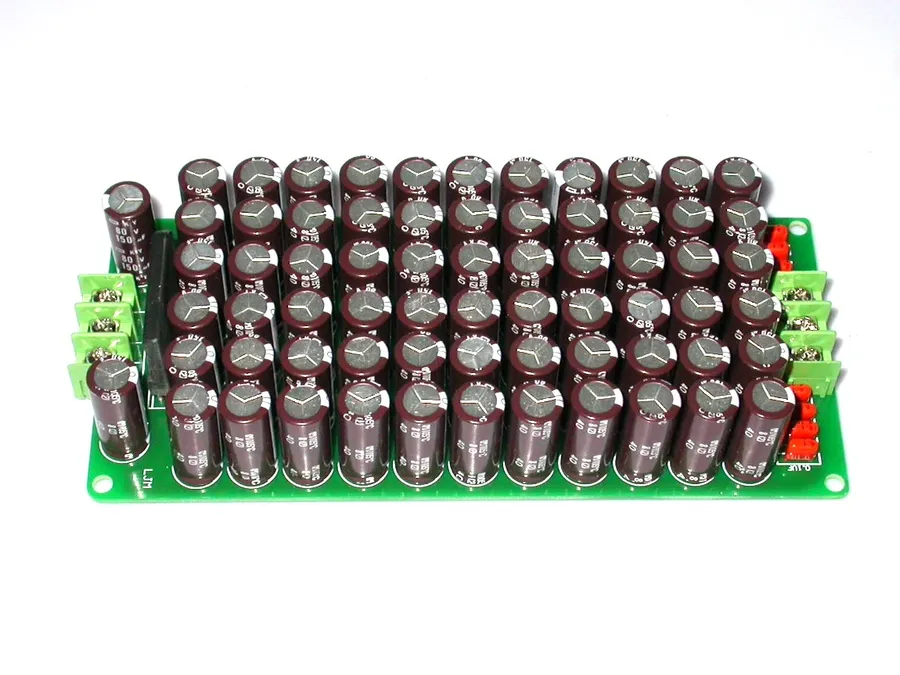

A 'large' capacitor is defined not merely by its physical size but primarily by its capacitance value, typically measured in Farads (F) or microfarads (µF). These components store electrical energy in an electric field. The term 'large' is relative and depends on the context. While a capacitor with a capacitance in the range of a few microfarads might be considered large for a small circuit, in high-power applications, it can be very small. Understanding this definition is crucial as the operational and performance characteristics of a capacitor are directly linked to its capacitance and physical dimensions.

The physical dimensions of a capacitor, such as its diameter and height (for cylindrical types) or surface area (for surface-mount types), often correlate with the capacitance. Larger physical sizes usually mean higher capacitance values, though this isn't always absolute due to differences in dielectric materials, internal structures, and manufacturing techniques. For instance, an electrolytic capacitor designed for high capacitance will typically be much larger than a ceramic capacitor with the same capacitance, and each has different performance implications. The size is also heavily influenced by its voltage rating which indirectly affects capacitor dimensions.

Types of Large Capacitors

Large capacitors, critical components in numerous electrical and electronic systems, are broadly categorized by their dielectric material and construction, each type exhibiting distinct characteristics, advantages, and limitations. This section delves into the four primary types of large capacitors: electrolytic, ceramic (MLCC), film, and supercapacitors, focusing on their unique attributes, performance trade-offs, and suitability for different applications.

| Capacitor Type | Dielectric Material | Capacitance Range | Voltage Range | Temperature Tolerance | Pros | Cons | Typical Applications |

|---|---|---|---|---|---|---|---|

| Electrolytic | Aluminum oxide, Tantalum pentoxide | High (µF to F) | Low to Medium | Moderate | High capacitance per volume, Relatively low cost | Polarized, Limited lifespan, Higher ESR | Power supplies, Smoothing circuits |

| Ceramic (MLCC) | Various ceramic compounds | Low to Medium (pF to µF) | Low to High | Good | Low ESR, Non-polarized, Wide temperature range | Capacitance varies with voltage and temperature, Fragile | Bypass capacitors, Signal decoupling, High frequency circuits |

| Film | Polyester, Polypropylene, other polymers | Medium (nF to µF) | Medium to High | Good | Low ESR, High reliability, Non-polarized | Larger size, higher cost compared to electrolytic | High-power circuits, AC filtering, Audio applications |

| Supercapacitor | Porous carbon, Metal oxides, conducting polymers | Very High (F) | Low | Moderate | Very high energy storage, Long cycle life | Low voltage rating, High cost per Farad | Energy harvesting, Backup power, Electric vehicles |

Applications of Large Capacitors

Large capacitors are indispensable components in numerous applications due to their ability to store significant amounts of electrical energy. Their applications span across diverse fields, from providing stable power to enabling high-energy discharges, demonstrating their versatility and critical role in modern electronics and energy systems.

Here are some key areas where large capacitors are utilized:

- Power Supplies

Large capacitors act as crucial filtering elements in power supplies, smoothing out voltage ripples and ensuring a stable DC output. This is essential for the reliable operation of sensitive electronic devices. For example, in a computer power supply, large electrolytic capacitors stabilize the output voltage, preventing fluctuations that could damage the components. - Motor Drives

In motor drive systems, large capacitors play a vital role in providing the surge currents required for starting and running motors. They store energy to assist during peak demand periods, enhancing motor performance and efficiency. They are often seen in industrial motor controllers, where they supply the energy needed for high torque applications. - Energy Storage Systems

Large capacitors, particularly supercapacitors, are increasingly used in energy storage applications. They can rapidly store and release energy, making them suitable for applications like regenerative braking systems in electric vehicles, where they store the energy generated during braking and release it during acceleration. This is a crucial application in renewable energy systems, where they can buffer the fluctuating energy supply from solar and wind sources. - Pulsed Power Applications

Large capacitors are essential in pulsed power systems, where they are used to deliver high-energy pulses for short durations. Applications range from scientific research like laser systems and electromagnetic launchers to industrial processes like welding and plasma generation. Here, their ability to rapidly discharge stored energy is key. - Audio Equipment

In high-fidelity audio amplifiers, large capacitors are used to decouple power supply noise and ensure a clean and stable power source for audio circuits. This significantly reduces noise and distortion, improving the overall audio quality. The larger the capacitor, the better the signal stability and clarity.

Large Capacitor Selection: Key Factors

Selecting the appropriate large capacitor for a given application requires a careful evaluation of several critical parameters. These parameters ensure optimal performance, reliability, and longevity within the intended operational environment. Key considerations include capacitance value, voltage rating, temperature coefficient, tolerance, Equivalent Series Resistance (ESR), and expected lifetime.

Below is a detailed explanation of the key factors to consider when selecting a large capacitor:

- Capacitance Value

The capacitance, measured in Farads (F), indicates the capacitor's ability to store electrical charge. Large capacitors typically have capacitance values ranging from microfarads (µF) to Farads. The required capacitance depends on the application; higher values are needed for energy storage and filtering applications, whereas lower values are used for signal processing. - Voltage Rating

The voltage rating specifies the maximum voltage that the capacitor can safely withstand without dielectric breakdown. It's crucial to choose a capacitor with a voltage rating higher than the maximum voltage expected in the circuit. Typically, a 20% safety margin is recommended to prevent premature failure. - Temperature Coefficient

This parameter describes how the capacitor's capacitance changes with temperature. A lower temperature coefficient is desirable for applications where stability is crucial, such as precision circuits. Capacitors with high temperature coefficients may not perform optimally in changing temperature conditions. - Tolerance

Capacitance tolerance indicates the range within which the actual capacitance value may vary from the nominal value. A smaller tolerance indicates a more precise capacitor. Tighter tolerances are typically required in precision circuits. The tolerance is usually given as a percentage, for example, ±5% or ±20%. - Equivalent Series Resistance (ESR)

ESR represents the internal resistance of the capacitor, which can cause power losses (heating) and reduce efficiency. Low ESR is crucial in high-current applications like power supplies where heat generation must be minimized. Lower ESR also results in better filtering performance. - Lifetime

Capacitor lifetime refers to the duration the component is expected to perform within specifications before significant degradation occurs. Lifespan is often specified in hours and is significantly affected by temperature and operating voltage. Choose a capacitor with a lifetime that meets or exceeds the application's requirement. This is critical for long-term reliability.

A simplified approach to estimating capacitor size is presented below. This method can help determine the capacitance value based on charge storage requirements or filtering needs.

For energy storage, use the following formula: C = (2 * Energy) / (V^2) where C is the Capacitance (in Farads), Energy is the total energy required to store in the capacitor (in Joules), and V is the voltage across the capacitor (in Volts). Ensure the capacitor's voltage rating exceeds the calculated V.

For filtering, a more complex analysis is needed, often involving impedance calculations and the frequency of the ripple voltage. You will typically need to find the impedance at the ripple frequency that reduces the ripple to a suitable level using the formula: Z = 1 / (2 * π * f * C), where f is the ripple frequency in Hz, and C is the capacitance in Farads. This calculation will provide an approximation of capacitance for a single frequency. However, real-world filters should consider the complete impedance and frequency response of the circuit.

Advantages of Using Large Capacitors

Large capacitors offer significant advantages in various electrical and electronic applications, primarily due to their substantial ability to store electrical charge. These benefits manifest in improved circuit performance, enhanced power delivery, and increased system stability. The increased capacitance provides superior performance in demanding applications.

- Effective Voltage Ripple Filtering

Large capacitors excel at smoothing out voltage fluctuations (ripples) in power supplies. Their large capacitance allows them to absorb and release energy efficiently, resulting in a more stable DC output. This is critical for sensitive electronic circuits that require a constant, clean power source. - Enhanced Power Delivery Smoothing

The high charge storage capacity of large capacitors provides a reservoir of energy, enabling them to quickly respond to sudden demands. This smoothing effect prevents voltage drops during peak loads, ensuring consistent performance of connected devices. This is particularly important for systems that require bursts of power. - Energy for Starting Loads

Large capacitors can store sufficient energy to provide the initial power surge needed to start motors and other inductive loads. They act as a temporary buffer, supplying the high current demand that may exceed the instantaneous capacity of the power source. This improves the reliability and efficiency of motor start-up. - Significant Energy Storage Capability

Large capacitors are not just for filtering; they can also be utilized for short-term energy storage. This capacity allows them to buffer power during brief interruptions or fluctuations, providing backup during short outages. This makes them valuable in systems needing a brief energy reserve. - Durability and Reliability

Large capacitors, especially those designed for industrial applications, are engineered for high durability and long operational life. Their robust construction and high energy density characteristics result in more reliable performance over time, offering long-term cost effectiveness.

Common Issues and Troubleshooting with Large Capacitors

Large capacitors, while robust, are susceptible to several failure modes that can impact their performance and lifespan. Understanding these issues and implementing proper troubleshooting techniques is crucial for ensuring the reliable operation of electronic systems. This section provides a comprehensive overview of common problems, their causes, and practical solutions.

- Aging and Degradation

Capacitor aging is a natural process that results in the gradual degradation of the dielectric material and the increase of Equivalent Series Resistance (ESR). This leads to a decrease in capacitance, increased energy dissipation (heat), and a higher probability of failure. Factors such as operating temperature, voltage, and ripple current accelerate the aging process. Regular testing can detect early signs of aging before a catastrophic failure. - Leakage Current

A small amount of leakage current is inherent in capacitors. However, excessive leakage can lead to energy loss and excessive heat generation. This can be caused by defects in the dielectric, overvoltage, or contamination. The leakage current often increases with temperature. Measurements using a multimeter can help identify leakage issues, and a comparison to datasheet specifications is advised. - Short Circuits

Short circuits in large capacitors can occur due to physical damage to the dielectric, material defects, overvoltage conditions, or improper mounting. Shorts can cause significant current flow, leading to component overheating, arcing, and potential explosions. It's essential to visually inspect capacitors for damage before installation and ensure correct voltage and current handling during operation. - Explosions and Ruptures

Capacitor explosions or ruptures, especially with electrolytic types, are often the result of internal pressure buildup from excessive heating, caused by overvoltage, reverse polarity, or excessive ripple current. This is a critical safety concern, which may lead to shrapnel generation and chemical leakage. Regular maintenance and preventative measures, including proper component selection, can reduce the risk of such events. Avoid applying voltage beyond the capacitor's specifications and never reverse the polarity for polarized capacitors. - Visual Inspection

Regular visual inspection can detect common failure indicators. Look for signs of bulging, leaks of electrolyte (in electrolytic capacitors), cracks in the casing, burn marks, or disconnected terminals. These are clear indications that a capacitor is nearing or has already reached its failure point and should be replaced as soon as possible. Always disconnect the circuit before any physical inspection. - Improper Handling and Storage

Physical damage from incorrect handling and inappropriate storage conditions can also cause premature failure. Avoid bending or twisting capacitor leads. Capacitors should be stored in a cool, dry environment, away from direct sunlight and corrosive materials. High temperatures and humidity can accelerate degradation. It is essential to store them within the manufacturer's recommended temperature and humidity ranges, which are often specified in datasheets.

Troubleshooting large capacitors involves a combination of visual inspection and electrical testing. When a faulty capacitor is identified, replacement is usually the most effective solution, followed by an investigation into the underlying causes of the failure. Regularly scheduled maintenance checks are also key to extending the life of your components. This includes measuring the ESR and capacitance to determine if they remain within specification.

Safety Precautions When Working with Large Capacitors

Working with large capacitors, especially high-voltage variants, demands strict adherence to safety protocols due to the potential for electrical shock and explosive failures. These devices store substantial electrical energy, which can be hazardous if mishandled. A thorough understanding of safe practices is paramount before any interaction.

- Understanding the Risks

Large capacitors, particularly those with high voltage ratings, store significant energy. This energy can cause severe electrical shocks, burns, and in some cases, explosions if the capacitor is short-circuited or overcharged. It is essential to treat these components with the utmost respect and caution. - Discharge Before Handling

Prior to any handling, a capacitor must be properly discharged. This is crucial even if the circuit is supposedly off because capacitors can retain charge for extended periods. Using an appropriate discharge tool, such as a resistor, is a recommended method to safely dissipate stored energy. Never rely on short-circuiting with a wire, as this can cause sparks, damage, or even explosion. - Appropriate Tools

Use insulated tools to handle capacitors. This minimizes the risk of electrical shock. When discharging, utilize resistors with appropriate voltage and power ratings to safely dissipate the stored energy. Avoid using metallic objects to discharge because of the risk of sudden current discharge, which can result in sparks or damage to the capacitor. - Personal Protective Equipment (PPE)

Always wear appropriate PPE, which includes insulated gloves and safety glasses. This equipment protects against shocks, burns, and any potential debris resulting from component failure during handling. In high-voltage environments, consider additional protection such as a face shield and electrically insulated clothing. - Avoid Contact with Terminals

Never touch the terminals of a charged capacitor. Always assume a capacitor is charged until verified otherwise through appropriate discharge procedures. Ensure that there are no potential pathways that would allow you to become part of the circuit, when handling the capacitor. - Post-Usage Handling

Even after discharge, a large capacitor might retain a small amount of residual charge. Store discharged capacitors in a safe environment where there will be no accidental short circuit. Ensure proper disposal procedures are followed because some capacitors contain materials harmful to the environment. - Visual Inspection

Regularly inspect capacitors for signs of damage, such as bulging cases, leaks, or burnt terminals. These indicate potential component failure and require careful handling. Do not use any damaged components. Replace or repair before use.

Large Capacitor vs. Small Capacitor: A Comparison

The distinction between 'large' and 'small' capacitors is primarily defined by their capacitance value, physical dimensions, and typical applications. While small capacitors are ubiquitous in electronics for basic filtering and timing, large capacitors are essential for high-power applications requiring significant energy storage or ripple smoothing. This section provides a comparative analysis to clarify their differences.

| Characteristic | Large Capacitor | Small Capacitor |

|---|---|---|

| Capacitance Value | Typically > 100µF, often in mF or Farad range | Typically < 100µF, often in pF or nF range |

| Physical Size | Larger, often cylindrical or rectangular packages | Smaller, often surface-mount or through-hole components |

| Voltage Rating | Can range from a few volts to kilovolts, often higher | Typically lower voltage ratings, often < 100V |

| Typical Applications | Power supplies, motor drives, energy storage, pulsed power | Signal filtering, timing circuits, bypass capacitors |

| Energy Storage Capability | High energy storage capacity | Low energy storage capacity |

| ESR (Equivalent Series Resistance) | Can vary; some types have higher ESR, which impacts heat dissipation | Generally lower ESR |

| Cost | Generally more expensive | Generally less expensive |

Frequently Asked Questions about Large Capacitors

This section addresses common questions regarding large capacitors, providing concise and authoritative answers to frequently asked questions, offering practical insights and addressing user's core concerns about large capacitors.

- What is Considered a Large Capacitor Value?

The definition of a 'large' capacitor is relative and depends on the application. However, generally, capacitors with values of 1 Farad (F) or more are considered large. In more typical electronic circuits, capacitors with values of 1000 microfarads (μF) or more are often considered large. The context, such as whether it's a power supply, audio, or motor drive circuit, will influence the definition of 'large'. - Is it Okay to Oversize a Capacitor?

Yes, in many cases, oversizing a capacitor (using one with a higher capacitance value than specified) is acceptable and can even be beneficial. A larger capacitor provides more charge storage and can better handle transient loads or voltage drops. However, it's crucial to verify the voltage rating to be equal or higher and to be aware of increased size, cost, and potentially longer charging/discharging times as well as possible inrush current if the circuit was not designed for it. - What Does a Large Capacitor Do?

Large capacitors primarily function as energy storage devices. They store electrical energy and can quickly release it as needed. They can perform several key functions: voltage smoothing, also known as filtering, to reduce voltage ripple in power supplies; providing a temporary power source during brief interruptions; or providing a high current surge, in pulsed power applications such as in radar systems. They are crucial components in power systems and applications requiring stable and reliable current. - What is the Use of a 1000 Microfarad Capacitor?

A 1000 μF capacitor is a common value in many electronic circuits and serves multiple purposes. It is frequently used for filtering and decoupling in power supplies. It helps stabilize the DC voltage by smoothing out AC fluctuations. It can be used for energy storage and for timing circuits. It is a versatile component used to maintain stable power for sensitive circuits, like in a control system or in an audio amplifier. - Why are large capacitors sometimes used in series or in parallel?

Large capacitors are frequently configured in series or parallel arrangements to meet specific circuit requirements. Connecting capacitors in series decreases overall capacitance while increasing the overall voltage rating, allowing for higher operating voltages. Conversely, parallel connections increase total capacitance, which can help provide more energy storage or filtering capacity. This flexibility allows engineers to fine-tune capacitor parameters. - What is the lifespan of a large capacitor?

The lifespan of a large capacitor depends on its type, operating conditions, and construction quality. Electrolytic capacitors have a finite lifespan due to electrolyte evaporation or degradation, with lifespan shortened by excessive temperature, voltage, or ripple current, and can last from a few years to over a decade. Film and ceramic capacitors generally last longer, usually beyond a decade, if properly used within their parameters. For critical applications, it's advisable to test and replace large capacitors periodically, especially electrolytic ones, to prevent circuit malfunctions.

In conclusion, large capacitors are indispensable components in modern electronics, facilitating energy storage, power filtering, and a range of other vital functions. Understanding their types, applications, and selection criteria is crucial for engineers and enthusiasts alike. By acknowledging their unique benefits and safety considerations, we can harness the full potential of these often-overlooked yet crucial devices, particularly in areas requiring a robust and reliable power source. As technology evolves, the role of large capacitors will continue to expand, driving innovation in energy storage and electronic design.

AnyPCBA

AnyPCBA