Unlocking Performance: A Deep Dive into Panasonic Capacitors

From the smartphones in our pockets to the sophisticated electronics powering our world, capacitors play a crucial, often unseen, role. Panasonic capacitors, renowned for their quality and reliability, are at the heart of many of these devices. This article delves into the diverse world of Panasonic capacitors, exploring their various types, applications, and what makes them a preferred choice for engineers and enthusiasts alike, bridging the gap between technology and everyday life.

The Spectrum of Panasonic Capacitor Types

Panasonic offers a diverse range of capacitors, each engineered for specific applications. This variety ensures optimal performance across different electronic circuits, encompassing aluminum electrolytic, polymer, and film capacitors. Each type possesses distinct characteristics regarding capacitance, voltage rating, equivalent series resistance (ESR), and temperature stability, dictating their suitability for various electronic designs.

| Capacitor Type | Key Characteristics | Typical Applications |

|---|---|---|

| Aluminum Electrolytic | High capacitance, cost-effective, polarized | Power supplies, audio equipment, general purpose filtering |

| Polymer (SP-Cap, OS-CON, POSCAP) | Low ESR, high ripple current, long life, polarized | Motherboards, servers, high-performance digital circuits |

| Film | Low loss, high precision, non-polarized, stable | Audio circuits, high-frequency circuits, precision timing |

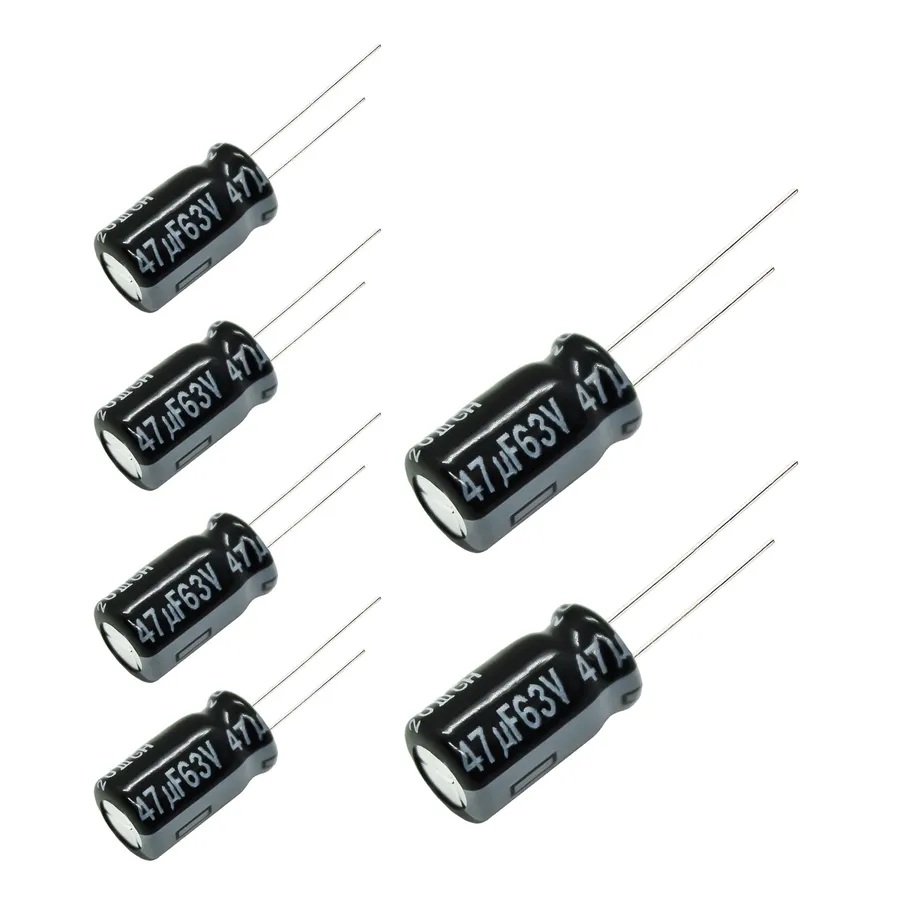

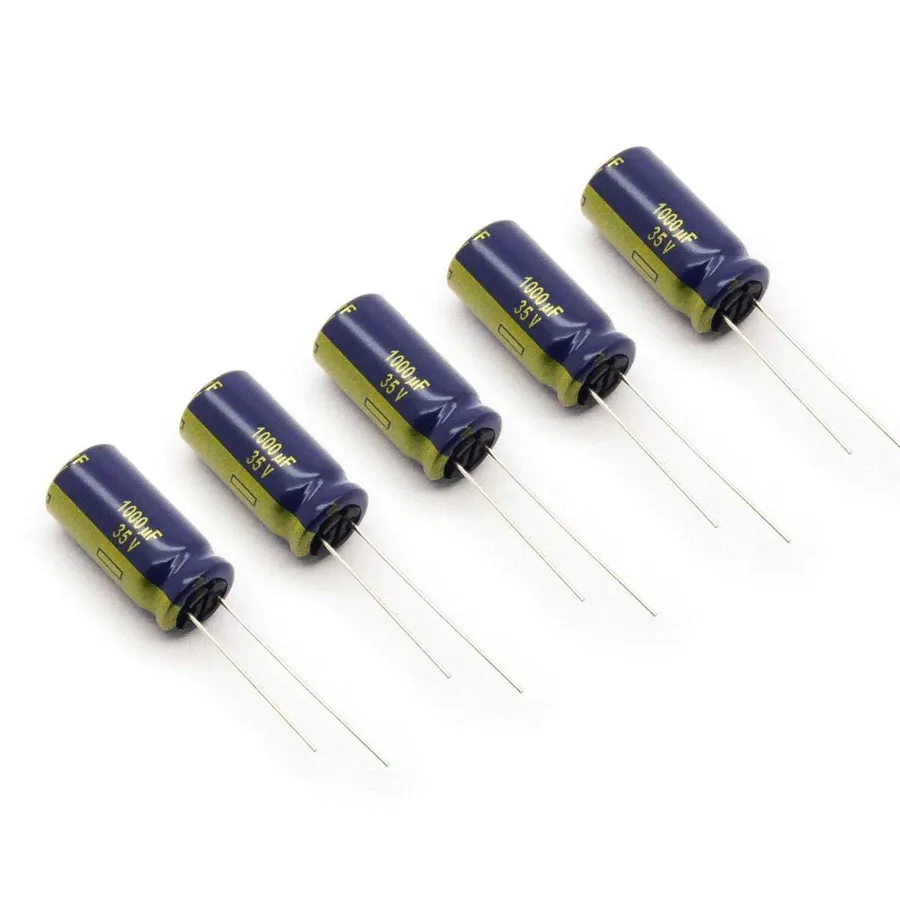

Panasonic Aluminum Electrolytic Capacitors: The Workhorse

Panasonic aluminum electrolytic capacitors are fundamental components in many electronic circuits, renowned for their high capacitance values and cost-effectiveness. These capacitors utilize an aluminum foil anode with an oxide dielectric layer, an electrolyte filling the space, and another foil acting as a cathode. This construction provides a compact solution for energy storage and filtering in a variety of applications.

| Feature | Description | Typical Applications |

|---|---|---|

| Construction | Aluminum foil anode with an oxide dielectric layer, electrolyte and a cathode foil. | Power Supplies, Audio Equipment |

| Capacitance Range | Typically very high, from microfarads (µF) to farads (F). | Bulk energy storage, filtering |

| Voltage Range | Available in various voltage ratings, from a few volts to several hundred volts. | Application specific |

| Cost-Effectiveness | Generally lower cost than other capacitor types. | General purpose applications |

| Advantages | High capacitance, cost-effective, suitable for AC and DC applications. | Wide range of electronic devices |

| Disadvantages | Limited lifespan and temperature range compared to polymer capacitors, higher ESR (Equivalent Series Resistance), polarity sensitive. | Requires careful design consideration |

Panasonic offers a diverse range of aluminum electrolytic capacitors, each optimized for specific applications. Their general-purpose series are widely used in power supplies for smoothing and decoupling, while specialized series cater to audio equipment where low impedance and high ripple current handling are critical. The long-established technology makes these capacitors very affordable.

Panasonic Polymer Capacitors: High Performance Champions

Panasonic polymer capacitors, including SP-Caps, OS-CON, and POSCAP series, represent a significant advancement in capacitor technology, offering superior performance characteristics such as low Equivalent Series Resistance (ESR) and high ripple current capabilities, making them ideally suited for demanding applications in high-performance electronics.

These capacitors utilize conductive polymers as their electrolyte material, which allows them to maintain stable performance under various operating conditions. This contrasts with traditional electrolytic capacitors, where liquid electrolytes can suffer from evaporation and performance degradation over time, especially at higher temperatures. Panasonic's polymer capacitors exhibit exceptional stability, reliability, and longevity, making them a preferred choice in applications where consistent performance is critical.

| Feature | SP-Cap | OS-CON | POSCAP |

|---|---|---|---|

| Electrolyte Material | Conductive Polymer | Conductive Polymer | Conductive Polymer |

| Typical ESR | Very Low | Low | Low |

| Ripple Current Capability | High | High | High |

| Operating Temperature Range | Wide | Wide | Wide |

| Application Focus | High-current DC-DC converters, consumer electronics | Power circuits, servers, industrial equipment | High-density power supply, portable devices |

The low ESR characteristics of Panasonic's polymer capacitors minimize power losses, enabling efficient energy transfer and heat dissipation. This is essential in applications with high-frequency switching or high-current demands, preventing component damage and improving overall system efficiency. Their high ripple current capabilities also provide robust performance under dynamic loading, maintaining stability and reliability in volatile conditions.

Specifically, SP-Caps are tailored for high-current applications such as DC-DC converters in consumer electronics. OS-CON capacitors, known for their superior noise absorption and ripple current capabilities, are typically used in high-performance power circuits, server applications, and industrial equipment, while POSCAP capacitors focus on high-density power supplies and portable devices.

Key Specifications and Performance Metrics

Selecting the correct capacitor for a specific application hinges on a thorough understanding of its key specifications. These parameters, such as capacitance, voltage rating, Equivalent Series Resistance (ESR), and ripple current, dictate the capacitor's performance and reliability within a circuit. Panasonic provides comprehensive datasheets that detail these specifications, enabling informed component selection.

| Parameter | Description | Units | Importance |

|---|---|---|---|

| Capacitance (C) | The ability of the capacitor to store an electrical charge. | Farads (F) | Determines energy storage capability and influences circuit time constants. |

| Voltage Rating (V) | The maximum DC voltage that can be safely applied across the capacitor terminals. | Volts (V) | Exceeding this rating can cause damage or failure of the capacitor. |

| Equivalent Series Resistance (ESR) | The internal resistance of the capacitor, contributing to power dissipation and heat generation. | Ohms (Ω) | Lower ESR is crucial for efficient high-frequency operation and ripple current handling. |

| Ripple Current (I) | The maximum AC current that the capacitor can handle continuously. | Amperes (A) | Exceeding this can lead to overheating and reduced capacitor lifespan, especially for electrolytic capacitors. |

| Operating Temperature Range | The temperature range within which the capacitor operates reliably. | Degrees Celsius (°C) | Ensures the capacitor operates within its design limits for reliability and performance. |

Panasonic datasheets provide detailed information on these parameters, often including graphs of impedance and ESR versus frequency, and temperature performance curves. For example, capacitance might be specified at a certain measurement frequency, and ESR might vary significantly depending on the operating frequency and temperature. Understanding these nuances is crucial for effective capacitor selection.

When selecting a capacitor, designers should refer to the manufacturer's datasheet, which often includes the following information:

- Part Number

The unique identifier for each specific capacitor model. - Rated Capacitance and Tolerance

Indicates the nominal capacitance value and the acceptable variation. - Rated Voltage

Specifies the maximum DC voltage that can be safely applied to the capacitor. - ESR Value

The Equivalent Series Resistance of the capacitor, usually dependent on frequency and temperature. - Ripple Current Rating

The maximum AC current the capacitor can continuously withstand. - Temperature Range

The operating temperature limits of the capacitor. - Datasheet Graphs

Often includes graphical representations of performance over frequency and temperature ranges

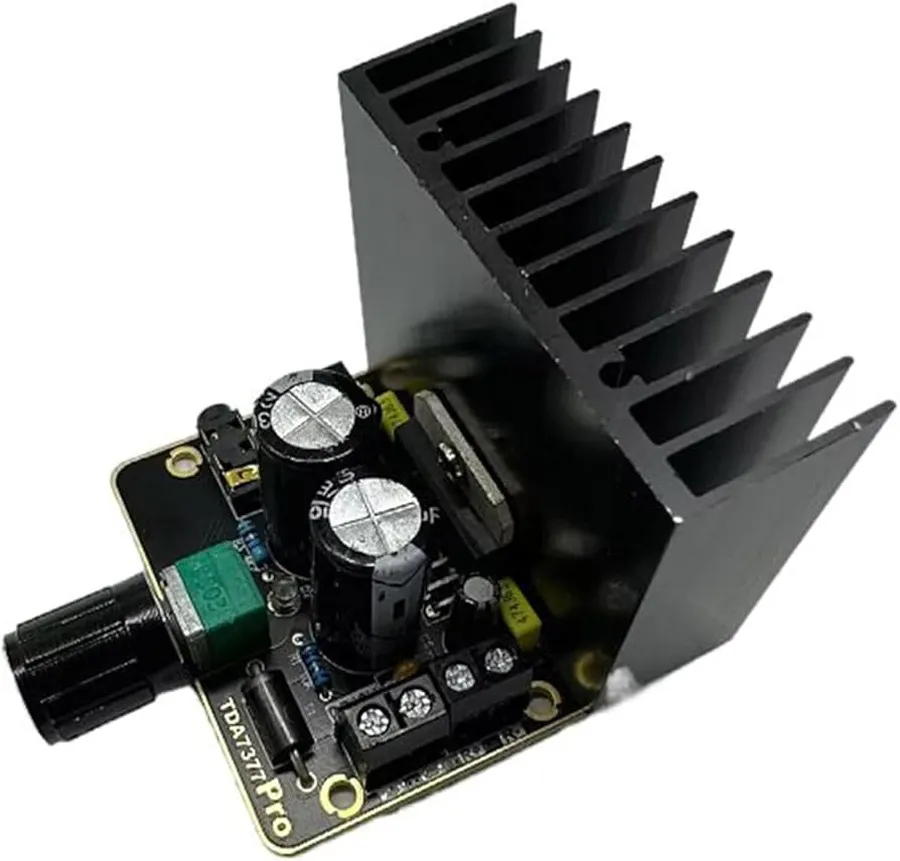

Panasonic Capacitors in Audio Applications

Panasonic capacitors play a crucial role in audio circuits, significantly contributing to signal fidelity, noise reduction, and overall sound quality. Their precise construction and high-quality materials make them a preferred choice for audio enthusiasts and professional audio equipment manufacturers.

The selection of capacitors in audio circuits is critical, and Panasonic offers specific series optimized for audio applications, such as the FC, FR, and the OS-CON lines. These capacitors are designed to minimize signal degradation and maintain the purity of the audio signal.

- Signal Clarity

Panasonic capacitors, especially those with low Equivalent Series Resistance (ESR), allow for minimal signal distortion and preserve the integrity of the audio signal, which results in a clearer and more accurate reproduction of sound. - Noise Reduction

The low impedance characteristics of Panasonic capacitors help to effectively filter out unwanted noise and interference in the audio signal path. This enhances the signal-to-noise ratio and allows for a cleaner, more immersive audio experience. - Enhanced Sound Quality

By using high-quality Panasonic capacitors, audio equipment can achieve superior dynamic range, precise imaging, and a more accurate tonal balance. This leads to an overall richer and more enjoyable listening experience.

Panasonic's diverse range of capacitors caters to different audio requirements, from budget-friendly consumer devices to high-end audiophile equipment. By carefully selecting the appropriate Panasonic capacitors, designers can optimize audio performance, ensuring exceptional sound reproduction and clarity.

Selecting the Right Panasonic Capacitor for Your Project

Choosing the correct Panasonic capacitor for a given project requires a thorough understanding of your application's demands and the capacitor's specifications. This selection process hinges on parameters like voltage requirements, operational temperature ranges, equivalent series resistance (ESR), and ripple current handling capabilities. It’s crucial to consult Panasonic's detailed datasheets, as this information is critical for ensuring reliable and optimal performance.

| Parameter | Description | Relevance to Capacitor Selection |

|---|---|---|

| Capacitance (F) | The amount of charge a capacitor can store at a given voltage. | Determines the capacitor's ability to hold electrical energy and impacts circuit behavior. |

| Voltage Rating (V) | The maximum voltage that can be safely applied to the capacitor. | Must exceed the highest voltage expected in the circuit to prevent damage or failure. |

| Equivalent Series Resistance (ESR) (Ω) | Resistance inherent in a capacitor, affecting its charging/discharging efficiency. | Crucial for high-frequency applications; lower ESR ensures minimal power loss and heat generation. |

| Ripple Current (A) | The AC current a capacitor can handle without overheating. | Essential for power supply applications to prevent overheating and component failure. |

| Operating Temperature Range (°C) | Temperature range within which the capacitor will operate safely and reliably. | Must match the thermal environment of the application to avoid performance degradation or failure. |

| Capacitor Type | The materials and design characteristics of the capacitor. | Different capacitor types have different strengths and weaknesses, impacting selection depending on the application. |

When comparing different capacitor types such as aluminum electrolytic, polymer, and film, consider the trade-offs between cost, size, performance, and lifespan. For instance, aluminum electrolytic capacitors offer high capacitance at a lower cost but have higher ESR and shorter lifespan compared to polymer capacitors. Polymer capacitors provide superior performance in high-frequency applications but can be more expensive. Film capacitors excel in high-precision and low-loss applications but may not be suitable for high-capacitance needs.

Frequently Asked Questions About Panasonic Capacitors

This section addresses common inquiries regarding Panasonic capacitors, providing essential information on their shelf life, lifespan, and comparisons with other brands. Understanding these aspects is crucial for selecting the optimal capacitor for specific applications.

- What is the optimal shelf life of Panasonic electrolytic capacitors?

Panasonic electrolytic capacitors typically have a shelf life of 2 to 3 years when stored under recommended conditions. These conditions usually involve temperature between 5 to 35 degrees Celsius and low humidity without direct sunlight. However, factors such as temperature and humidity can significantly impact their lifespan. It is critical to check the specific datasheet for each series to obtain precise storage guidelines, as some series may have specific requirements. - What factors determine the lifespan of a Panasonic capacitor?

The lifespan of a Panasonic capacitor depends on several factors including operating temperature, applied voltage, ripple current, and the capacitor's construction. Higher operating temperatures accelerate the degradation of the capacitor's internal materials, most notably the electrolyte in electrolytic capacitors, shortening its life. Overvoltage and excessive ripple current can lead to overheating and premature failure. Selecting components operating within their specified rating and minimizing the operating temperature can improve longevity significantly. - What are the key differences between Panasonic electrolytic and polymer capacitors?

Panasonic electrolytic capacitors offer high capacitance and cost-effectiveness, making them suitable for applications requiring bulk energy storage. They tend to have higher ESR values. Polymer capacitors, such as SP-Caps, OS-CON, and POSCAP, feature lower ESR values, higher ripple current capabilities and greater stability, making them suitable for high-frequency switching applications. The choice depends on the specific application requirements and balancing the cost and the performance characteristics of both capacitor types. - Which type of capacitor generally has the longest lifespan?

Film capacitors generally exhibit the longest lifespan due to their stable dielectric material and robust construction, making them suitable for demanding applications. Ceramic capacitors also have a very long shelf life but are typically lower capacitance value capacitors. Electrolytic capacitors, while offering high capacitance, typically have a shorter lifespan due to the electrolyte drying out over time, especially at elevated temperatures. - What are the best practices for extending the life of Panasonic capacitors in a circuit?

To maximize the lifespan of Panasonic capacitors, ensure they operate within the manufacturer's specified temperature and voltage ratings. Avoid excessive ripple currents and consider using cooling techniques to reduce operational temperature. Careful design practices, such as proper placement and thermal management of the capacitor, can dramatically extend its lifespan. It is critical to select components with derated voltage, temperature and ripple current values to increase safety margins and longevity. - How do I identify the correct Panasonic capacitor for my project?

Selecting the right Panasonic capacitor requires careful consideration of various parameters. Begin by identifying the required capacitance value, operating voltage, and temperature range for your application. Evaluate the ESR (Equivalent Series Resistance) and ripple current requirements, as these parameters will help determine the capacitor's suitability for high-frequency or high-current applications. Always refer to the manufacturer's datasheets for detailed specifications. Using simulation tools is a great aid when you have multiple design options. - How do Panasonic capacitors compare with other brands?

Panasonic capacitors are well-regarded for their quality, reliability, and performance consistency. They often feature innovative designs and a wide range of options to suit a variety of applications. While brands like Murata and TDK also offer high-quality capacitors, the choice ultimately depends on specific requirements, considering specifications, cost, and availability. Direct comparisons using specification sheets are always the best way to do this.

Comparing Panasonic Capacitors with Competitors

While Panasonic is a leading manufacturer of capacitors, a comparison with competitors provides a comprehensive view of the market landscape. This section highlights the strengths and weaknesses of Panasonic capacitors when placed alongside other major brands, focusing on key parameters and application suitability.

| Feature | Panasonic | Murata | TDK | Vishay | Samsung Electro-Mechanics |

|---|---|---|---|---|---|

| Technology Focus | Wide range, emphasis on electrolytic, polymer, and film capacitors | Primarily ceramic capacitors, but also has aluminum and polymer. | Broad range including ceramic, film, and electrolytic capacitors. | Strong in tantalum and film capacitors, also offers aluminum electrolytic capacitors. | Strong in multilayer ceramic capacitors (MLCCs) and tantalum capacitors. |

| Electrolytic Capacitors | High capacitance, cost-effective, suitable for general-purpose power supply applications | Good quality aluminum electrolytic and polymer but fewer options than Panasonic | Good performance in low voltage and high-temperature applications | Wide range, emphasis on high voltage ratings | Competent range of electrolytic capacitors for various uses. |

| Polymer Capacitors | Excellent low ESR and high ripple current capabilities, ideal for high-performance applications | Offers Polymer capacitors with a focus on high reliability | Good performance, but may not have as many options as Panasonic | Offers some polymer capacitors, focused on high reliability | Increasing presence in polymer capacitors, but may not match Panasonic's performance range. |

| Ceramic Capacitors | Offers a range, but not their primary focus | Global leader in MLCC technology with high-quality range. | Strong product line in ceramic capacitors. | Limited selection in ceramic capacitors. | A major manufacturer of MLCC with strong global presence. |

| Film Capacitors | Wide range, good for high-voltage and high-frequency applications | Has a range of film capacitors but does not compete as directly with Panasonic. | Offers film capacitors with wide operating temperature range. | Strong in film capacitors, focus on high voltage and automotive applications | Offers some film capacitors, typically in high-end applications |

| Strengths | Broad product line, strong reputation for reliability and quality, innovative technology in polymer capacitors | Industry leader in ceramic capacitors, high quality | Wide variety of capacitors, good reputation for quality | Strong focus on film and tantalum, wide range of specialty capacitors | High quality MLCC and a growing range of high-performance capacitors |

| Weaknesses | May not be as competitive in some niche ceramic applications. | Limited in product range outside of ceramic capacitors. | Slightly less emphasis on polymer compared to Panasonic | Limited in polymer capacitors | May not have as many options in polymer compared to Panasonic |

This comparison shows that while Panasonic has a strong presence across various capacitor technologies, each competitor has its unique strengths. Murata and Samsung Electro-Mechanics lead in ceramic capacitors, Vishay excels in tantalum and film capacitors, and TDK offers a comprehensive range. Panasonic distinguishes itself with a particularly strong portfolio in polymer capacitors and reliable performance across all lines. The choice of capacitor brand ultimately depends on the specific application needs and performance requirements.

Future Trends in Panasonic Capacitor Technology

Panasonic is at the forefront of capacitor technology, continually innovating to meet the evolving demands of modern electronics. Future trends in Panasonic capacitor technology are centered around advancements in material science, design, and application, pushing the boundaries of performance and reliability.

Key areas of focus include:

- Material Innovations

Exploring new dielectric materials with higher permittivity and lower loss, allowing for smaller and more efficient capacitors. Research into self-healing materials is also a growing area of interest, enhancing capacitor reliability and longevity. - Miniaturization and Integration

Continuing to reduce capacitor size while maintaining performance, driven by the demand for smaller devices. Integration of capacitor technology into multi-functional components is another trend, streamlining design and reducing PCB footprint. - Enhanced Thermal Performance

Developing capacitors that can operate at higher temperatures without significant degradation in performance. This is crucial for applications in automotive, industrial, and aerospace environments. Advanced heat dissipation techniques are also being explored. - High-Voltage Capabilities

Pushing the boundaries of voltage ratings to meet the requirements of emerging technologies, particularly in power electronics and renewable energy applications. Development of new electrode materials and structures to support higher voltages is key. - Improved Reliability and Lifetime

Focusing on enhanced reliability and extended operational lifespan, particularly for applications where component failure can have significant consequences, like automotive and medical devices. This involves careful material selection and design optimization. - Integration with Emerging Technologies

Developing capacitors tailored for new and rapidly evolving fields, such as 5G communications, electric vehicles, renewable energy systems, and advanced AI hardware. Customization to specific application requirements is becoming increasingly important.

Panasonic's ongoing commitment to research and development will ensure that its capacitors continue to play a vital role in the advancement of electronic technology. Their focus on material science, design optimization, and applications across a variety of emerging sectors will likely result in a new generation of high-performing, efficient, and reliable capacitors.

Panasonic capacitors represent a benchmark in the electronics industry, known for their reliability, performance, and wide range of applications. From the robust aluminum electrolytic to the high-performance polymer series, Panasonic's commitment to innovation ensures that electronic devices, small and large, are built on a foundation of quality. As technology evolves, Panasonic continues to push the boundaries of capacitor design, playing a pivotal role in shaping the future of electronics and our interaction with it.

AnyPCBA

AnyPCBA