Unlocking the Power of Ultracapacitors: A Comprehensive Guide

In our ever-evolving quest for efficient and sustainable energy solutions, ultracapacitors emerge as a revolutionary technology. Imagine a device that can store and release energy almost instantaneously, far surpassing the capabilities of traditional batteries. This article delves deep into the world of ultracapacitors, exploring their core mechanisms, their practical applications, and how they are shaping the future of energy storage. Join us as we uncover the potential of these remarkable components, bridging the gap between science and everyday life.

Understanding Ultracapacitor Basics

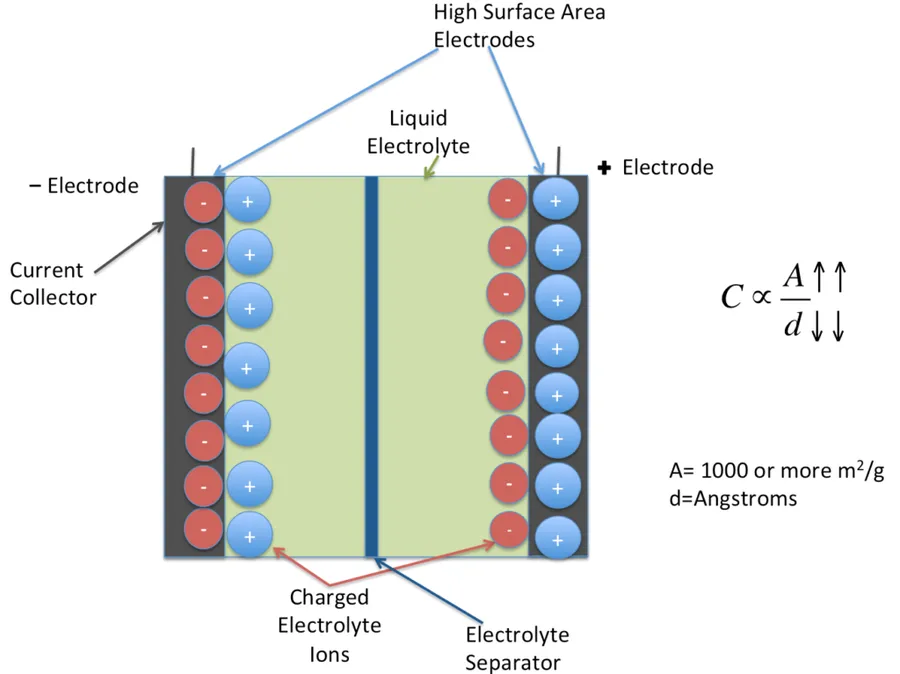

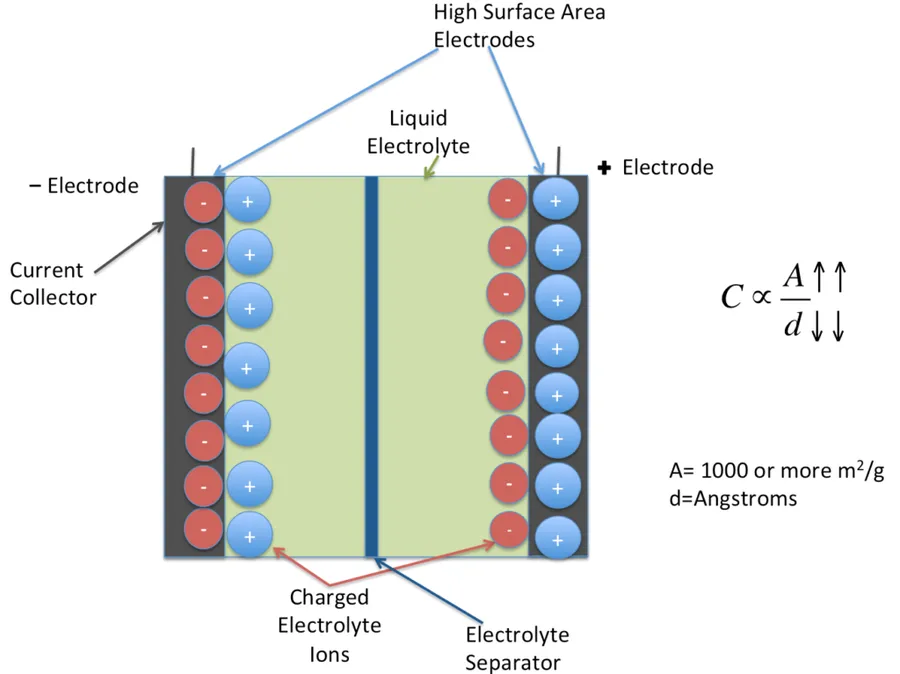

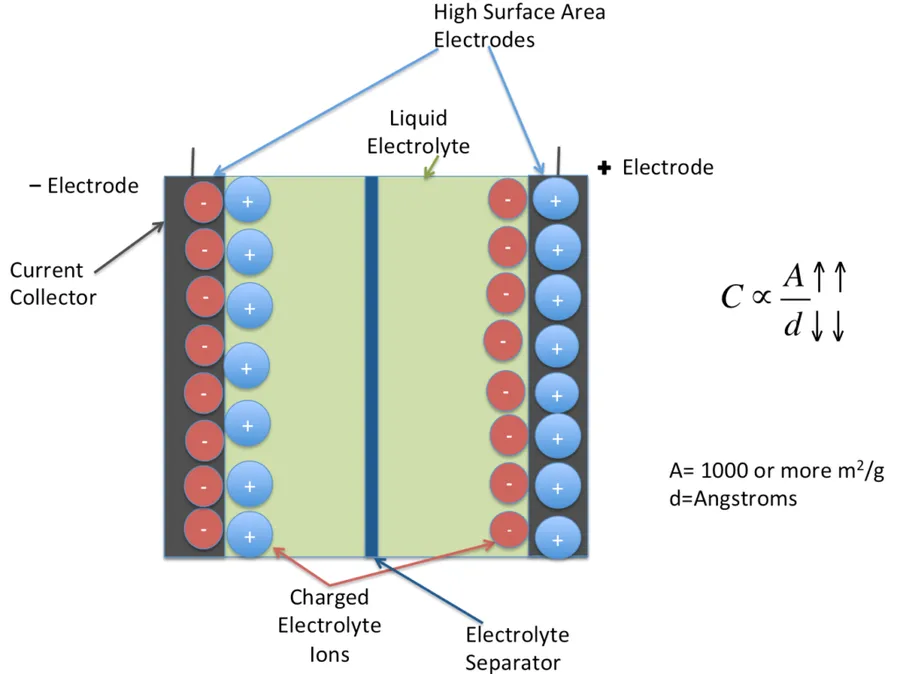

An ultracapacitor, also known as a supercapacitor or electrochemical double-layer capacitor (EDLC), is an electrochemical energy storage device that bridges the performance gap between traditional capacitors and batteries. Unlike conventional capacitors that store energy electrostatically, ultracapacitors store energy by accumulating ions at the electrode-electrolyte interface, resulting in significantly higher energy storage capacity compared to capacitors and far faster charging and discharging than batteries. This section will delve into their unique construction and operational principles.

The fundamental difference lies in their charge storage mechanism. Standard capacitors accumulate charge through electrostatic attraction using an insulator, known as a dielectric, between two conductive plates. Batteries rely on chemical reactions to convert chemical energy into electrical energy. Ultracapacitors, on the other hand, employ an electrochemical double-layer phenomenon. This phenomenon involves the formation of oppositely charged layers at the interface between an electrode and an electrolyte. It allows for high surface area, leading to increased capacitance without undergoing chemical transformation of the electrode material, distinguishing it from batteries, and allows faster charging and discharging than capacitors.

| Feature | Standard Capacitor | Ultracapacitor | Battery |

|---|---|---|---|

| Energy Storage Mechanism | Electrostatic | Electrochemical double-layer | Electrochemical reaction |

| Energy Density | Very Low | Medium | High |

| Power Density | Medium | Very High | Low |

| Charge/Discharge Rate | Very Fast | Very Fast | Slow |

| Cycle Life | Very High | Very High | Low |

The construction of an ultracapacitor typically involves two porous electrodes, usually made of materials like activated carbon, separated by an electrolyte solution and a separator. When a voltage is applied, ions from the electrolyte migrate to the surface of the electrodes, creating the electric double layer. The separator ensures that the electrodes do not make electrical contact, while the electrolyte facilitates ion transport. The overall design allows for efficient, rapid charging and discharging, due to the primarily physical, rather than chemical, nature of energy storage.

Key Advantages of Ultracapacitors

Ultracapacitors, also known as supercapacitors, offer a compelling set of advantages over traditional energy storage devices like batteries and conventional capacitors. Their unique characteristics make them suitable for applications requiring rapid energy delivery and high cycle life. These advantages stem from their electrochemical double-layer capacitance (EDLC) mechanism, which stores energy electrostatically, differentiating them from batteries that store energy through chemical reactions.

| Feature | Ultracapacitors | Batteries |

|---|---|---|

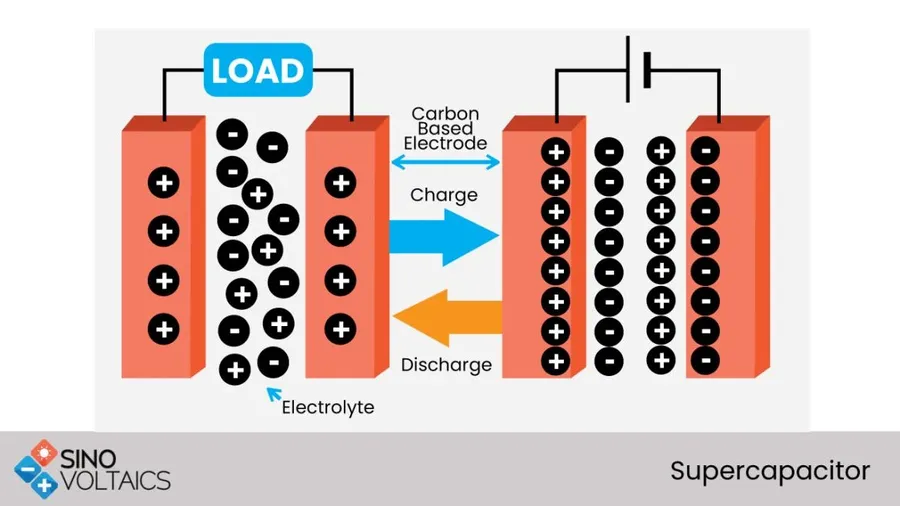

| Charging/Discharging Rate | Extremely rapid (seconds to minutes) | Slow (hours) |

| Cycle Life | Very high (hundreds of thousands to millions of cycles) | Limited (hundreds to thousands of cycles) |

| Power Density | High (suitable for high-power bursts) | Lower |

| Energy Density | Lower (compared to batteries) | Higher (compared to ultracapacitors) |

| Operating Temperature | Wider Range | More Limited |

| Safety | Generally safer; less prone to thermal runaway | Can be prone to thermal runaway under specific conditions |

- Rapid Charging and Discharging

Ultracapacitors excel in applications where power needs to be delivered or absorbed quickly. Their electrostatic energy storage mechanism allows for extremely fast charge and discharge cycles, often within seconds or minutes, a stark contrast to the slower charging times of batteries. - Long Lifespan

The life cycle of an ultracapacitor far exceeds that of batteries. They can endure hundreds of thousands, even millions of charge and discharge cycles with minimal degradation. This translates to significantly lower replacement costs and a reduced environmental impact over their operational lifespan. - High Power Density

Ultracapacitors offer superior power density compared to batteries, meaning they can deliver large amounts of power in a short period of time. This makes them ideal for applications such as regenerative braking in vehicles and pulsed power systems. - Wide Operating Temperature Range

Ultracapacitors typically operate over a wider temperature range than batteries, making them suitable for use in more extreme environmental conditions. - Safety

Ultracapacitors are generally considered safer than batteries, with a lower risk of thermal runaway, because energy storage is electrostatic rather than electrochemical.

Ultracapacitor vs. Supercapacitor: Are They the Same?

The terms 'ultracapacitor' and 'supercapacitor' are effectively synonymous, referring to the same class of electrochemical energy storage devices. While subtle distinctions have been proposed, in practical and commercial applications, they are used interchangeably. Both terms describe devices that bridge the gap between traditional capacitors and batteries, offering higher energy storage than the former and greater power delivery than the latter.

The interchangeable use of these terms can be attributed to their shared operating principles: they store energy electrostatically, through the accumulation of ions at the interface between an electrode and an electrolyte. This mechanism differs from batteries, where energy storage relies on chemical reactions. While some may suggest that 'ultracapacitor' implies a slightly higher performance or newer technology, this distinction is not universally adopted or meaningful in the current industry.

Ultracapacitor Applications Across Industries

Ultracapacitors, distinguished by their rapid charge-discharge cycles and high power density, are finding diverse applications across various industries. Their unique ability to deliver large amounts of power quickly and efficiently, bridges the gap between traditional capacitors and batteries, unlocking new possibilities in various sectors.

- Electric Vehicles (EVs) and Hybrid Electric Vehicles (HEVs)

Ultracapacitors are used in regenerative braking systems to capture and store energy during deceleration, providing an immediate power boost during acceleration. This reduces the load on batteries, extending their lifespan and improving overall vehicle efficiency. - Renewable Energy Systems

In solar and wind energy systems, ultracapacitors help manage the intermittent nature of renewable energy sources by providing short-term energy storage to smooth out fluctuations in power generation. This ensures a more stable and reliable energy supply. - Public Transportation

Ultracapacitors are implemented in electric buses and trams for regenerative braking. Their quick charge times make them ideal for frequent stop-and-go operations. They also serve as a backup power source, guaranteeing uninterrupted service. - Consumer Electronics

Ultracapacitors are utilized in portable devices like laptops, tablets, and smartphones to support high-power functions such as rapid charging and flash photography, offering a durable and efficient alternative to conventional batteries. - Industrial Equipment

In industrial settings, ultracapacitors provide backup power for critical equipment, handle peak power demands, and power material handling machinery, increasing operational reliability. - Grid Stability

Beyond small-scale uses, ultracapacitors are used in grid-scale energy storage systems. Their high power density and fast response times help in voltage regulation and frequency stabilization. - Aerospace

Ultracapacitors are finding applications in aircraft for auxiliary power systems, energy storage, and load leveling, enhancing performance and efficiency.

Ultracapacitor Technology Deep Dive

Ultracapacitor technology encompasses a range of designs and material choices, all aimed at maximizing energy storage and power delivery. These technologies diverge primarily in electrode materials, electrolyte types, and cell construction, each influencing the device's performance, cost, and application suitability.

The performance characteristics of an ultracapacitor are significantly affected by the technology employed. The following list details common technologies, materials, and manufacturing processes that impact performance.

- Electrode Materials

The electrode material largely determines the performance of an ultracapacitor. Common materials include: Activated Carbon, offering a cost-effective solution with high surface area; Carbon Nanotubes and Graphene, providing superior conductivity and surface area, leading to higher performance; and Metal Oxides and Conducting Polymers, which are often employed to enhance capacitance and voltage. - Electrolyte Types

Electrolytes play a vital role, influencing the voltage window, ionic conductivity, and operational temperature range of the ultracapacitor. They are primarily classified into aqueous, organic, and ionic liquids. Aqueous electrolytes provide high conductivity but are limited by their electrochemical window. Organic electrolytes offer a wider voltage range, while ionic liquids exhibit high thermal stability, and increased electrochemical window, but have lower conductivity. - Cell Construction and Design

Ultracapacitor designs may be either symmetric or asymmetric depending on the electrodes used. Symmetric designs involve identical electrode materials, which simplifies manufacturing but might limit performance. Asymmetric designs use different electrodes to enhance performance. Cell design includes parameters like electrode thickness, current collector material, and separator type, which directly affect device performance and reliability. - Manufacturing Processes

Manufacturing processes for ultracapacitors are continually being improved to increase efficiency and reduce costs. Electrode production involves methods such as coating, printing, and deposition. Cell assembly is performed either by winding, stacking, or other specific methods, while activation and testing ensure optimal performance of the final device. These manufacturing steps have a great effect on cost and reliability.

| Technology Aspect | Description | Impact on Performance |

|---|---|---|

| Electrode Material: Activated Carbon | Cost-effective with high surface area | Moderate capacitance, good power handling |

| Electrode Material: Carbon Nanotubes/Graphene | Superior conductivity and surface area | High capacitance, excellent power handling |

| Electrode Material: Metal Oxides/Conducting Polymers | Increased capacitance and voltage | Improved energy storage capability |

| Electrolyte Type: Aqueous | High conductivity, limited voltage | Good power, narrow operational voltage |

| Electrolyte Type: Organic | Wider voltage range | Higher energy storage potential |

| Electrolyte Type: Ionic Liquids | High thermal stability, wide electrochemical window | High temperature operation |

| Cell Design: Symmetric | Identical electrodes, simpler design | Good reliability, balanced performance |

| Cell Design: Asymmetric | Different electrodes, complex | Improved performance, higher energy |

Ultracapacitor Performance Metrics and Specifications

Understanding the performance metrics of ultracapacitors is crucial for effective application. These metrics dictate the device's suitability for various energy storage needs. Key specifications include capacitance, voltage, and Equivalent Series Resistance (ESR), each playing a critical role in overall performance.

| Metric | Description | Units | Impact on Performance |

|---|---|---|---|

| Capacitance (C) | The amount of electrical charge an ultracapacitor can store. | Farads (F) | Higher capacitance equates to more energy storage capability. |

| Voltage (V) | The maximum operating voltage of the ultracapacitor. | Volts (V) | Determines the energy level, higher voltages store more energy given the same capacitance. |

| Equivalent Series Resistance (ESR) | The internal resistance of the ultracapacitor. | Ohms (Ω) | Lower ESR results in less power loss as heat and more efficient power delivery. |

| Power Density | The rate at which energy can be delivered, typically measured in kilowatts per kilogram. | W/kg | Indicates how quickly an ultracapacitor can charge or discharge, critical for high-power applications. |

| Energy Density | The total amount of energy an ultracapacitor can store, typically measured in watt-hours per kilogram. | Wh/kg | Determines the amount of energy a device can store in relation to its weight. |

| Cycle Life | The number of charge and discharge cycles an ultracapacitor can endure before performance degradation. | Cycles | Reflects the longevity of an ultracapacitor. |

Frequently Asked Questions About Ultracapacitors

This section addresses common questions about ultracapacitors, providing clear, concise answers to help clarify their functionality, limitations, and potential applications.

- What are the primary applications of ultracapacitors?

Ultracapacitors excel in applications requiring rapid energy storage and release, such as regenerative braking in vehicles, burst power for industrial machinery, and energy buffering in renewable energy systems. Their ability to handle frequent charge-discharge cycles makes them ideal for these scenarios. - Can ultracapacitors completely replace batteries?

While ultracapacitors offer superior power density and cycle life, they generally have lower energy density compared to batteries. They are not a direct replacement for all battery applications. Instead, they complement batteries, often working in hybrid systems where ultracapacitors handle peak power demands and batteries provide sustained energy. - What are the key limitations of ultracapacitors?

The main limitations of ultracapacitors include their relatively lower energy density compared to batteries, which means they cannot store as much energy for a given size and weight. They also exhibit a linear voltage drop during discharge, unlike batteries which maintain a relatively stable voltage output. - Are ultracapacitors the same as supercapacitors?

The terms 'ultracapacitor' and 'supercapacitor' are often used interchangeably to describe the same energy storage device. There are no significant differences between them; the terms reflect historical naming conventions more than technical distinctions. - Do ultracapacitors degrade over time with use?

Ultracapacitors exhibit minimal degradation over their extensive cycle life, typically lasting for hundreds of thousands to millions of cycles with a small decrease in capacitance. This is unlike batteries, which degrade more significantly with each charge-discharge cycle, making ultracapacitors ideal for applications with frequent use. - What is the typical charging time for an ultracapacitor?

Ultracapacitors can be charged extremely quickly, often within seconds to minutes, due to their unique electrochemical mechanisms that do not involve chemical reactions. This fast charge time is one of their primary advantages over batteries, which require longer charging periods. - What are some key performance metrics to consider when evaluating ultracapacitors?

Key performance metrics include capacitance (measured in Farads), voltage, ESR (Equivalent Series Resistance, measured in Ohms), and energy density (measured in Wh/kg or Wh/L). These parameters determine the device's ability to store and deliver energy efficiently.

Future Trends and the Potential of Ultracapacitors

The field of ultracapacitors is rapidly evolving, driven by the increasing demand for efficient and sustainable energy storage solutions. Ongoing research focuses on enhancing energy density, power density, and lifespan, while simultaneously reducing cost and environmental impact. These advancements promise a transformative impact across numerous industries, from transportation to renewable energy integration.

Current research efforts are centered on several key areas:

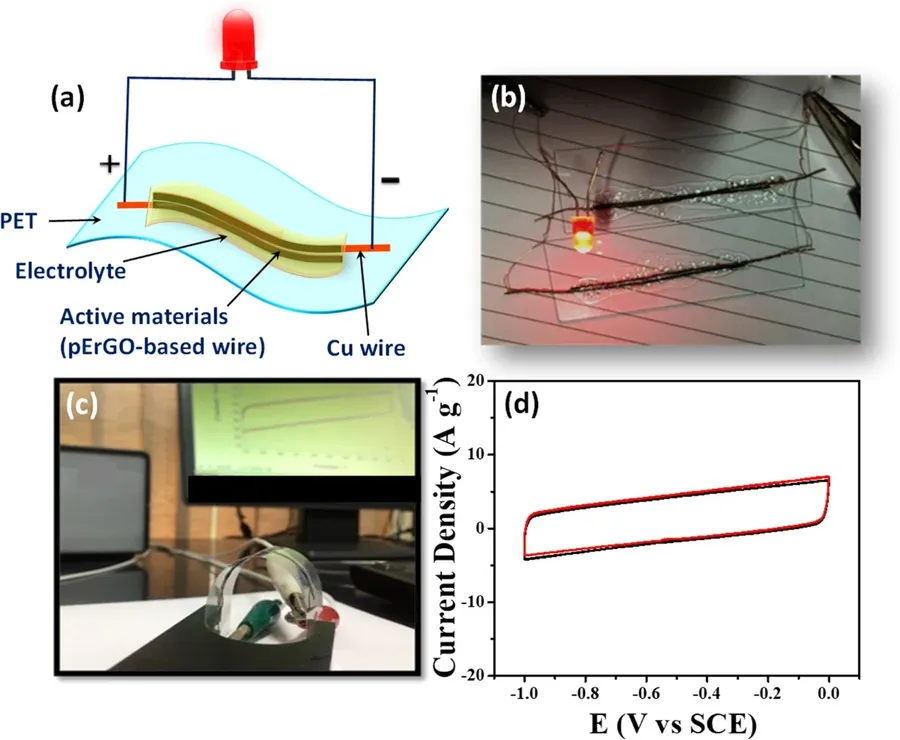

- New Materials and Nanotechnology

Researchers are exploring advanced materials like graphene, carbon nanotubes, and MXenes to create electrodes with higher surface areas and improved conductivity, resulting in enhanced energy storage capacity and faster charge/discharge rates. - Electrolyte Innovations

Novel electrolytes, including ionic liquids and solid-state electrolytes, are being developed to extend the operating temperature range, improve safety, and reduce the internal resistance of ultracapacitors. - Hybrid Energy Storage Systems

Combining ultracapacitors with batteries in hybrid systems is gaining traction, leveraging the high power density of ultracapacitors for peak power demands and the high energy density of batteries for extended storage. - Advanced Manufacturing Techniques

Efforts are being made to develop scalable and cost-effective manufacturing techniques, such as 3D printing and roll-to-roll processes, to reduce production costs and increase the availability of ultracapacitors. - Integration with Renewable Energy

Ultracapacitors are increasingly important in renewable energy systems, such as solar and wind, due to their ability to efficiently capture and release energy fluctuations, ensuring grid stability.

The potential impact of these developments is substantial. Improved ultracapacitors could revolutionize electric vehicle technology by enabling faster charging and more efficient regenerative braking. Their integration into public transportation systems, such as buses and trains, could lead to more sustainable and efficient urban transport. Furthermore, the advancements in renewable energy integration will enable more stable and reliable clean energy grids, reducing dependence on fossil fuels. The convergence of materials science, electrochemistry, and manufacturing is driving the ultracapacitor technology forward, promising a future where energy storage is efficient, sustainable, and readily accessible.

Choosing the Right Ultracapacitor: A Practical Guide

Selecting the optimal ultracapacitor for a specific application requires a thorough understanding of the application's demands and careful evaluation of available ultracapacitor characteristics. This guide provides actionable tips and a comparative analysis to aid in that process, focusing on performance, cost, and durability.

Before choosing an ultracapacitor, you must first accurately define your performance requirements. Start by determining the necessary capacitance, operating voltage, and current demands of your application. Also, consider the operating temperature range and required cycle life. These factors will help you narrow down potential choices.

The following table compares common performance factors for various use cases, it is important to note that values can vary greatly depending on the specific ultracapacitor model.

| Performance Factor | Low Power Application (e.g., small electronics) | Medium Power Application (e.g., Hybrid Vehicles) | High Power Application (e.g., industrial equipment) |

|---|---|---|---|

| Capacitance (Farads) | 0.1 - 10F | 100 - 1000F | 1000+F |

| Operating Voltage | 2.7-5.5V | 12-48V | 48V+ |

| ESR (mΩ) | 100-1000mΩ | 1-10mΩ | <1mΩ |

| Cycle Life | 100,000+ cycles | 500,000+ cycles | 1,000,000+ cycles |

| Cost | Low | Medium | High |

After carefully evaluating technical specifications, consider the cost versus performance tradeoff for each ultracapacitor option. Higher performance ultracapacitors may be more expensive, but can often provide improved efficiency and longevity. Also, it is essential to verify the ultracapacitor's durability for its intended application. This includes its temperature tolerance, susceptibility to humidity, and resistance to physical shocks. Selecting a product with a sufficient margin of safety can greatly extend its operational lifespan and reliability.

By carefully analyzing the performance requirements, specifications, costs, and durability of available ultracapacitors, you can confidently select the ideal ultracapacitor for your particular use case, thus maximizing both performance and efficiency.

Ultracapacitors represent a paradigm shift in energy storage. Their ability to rapidly store and release energy, coupled with their extended lifespan, positions them as a crucial technology for the future. From powering electric vehicles to stabilizing renewable energy grids, ultracapacitors are at the forefront of a revolution, offering a sustainable and efficient alternative to traditional batteries and setting the stage for future innovation. Understanding and harnessing the potential of ultracapacitors is crucial for addressing our growing energy needs while minimizing environmental impact.

AnyPCBA

AnyPCBA