Unveiling the Power of Polypropylene Capacitors: A Comprehensive Guide

From the smooth operation of your home appliances to the intricate systems in industrial machinery, capacitors play a crucial role. Among them, the polypropylene capacitor stands out for its exceptional stability and performance. This article will uncover the secrets behind this versatile component, exploring its characteristics, applications, and why it's a go-to choice in many electrical designs, bridging the gap between daily technology and cutting-edge engineering.

What is a Polypropylene Capacitor?

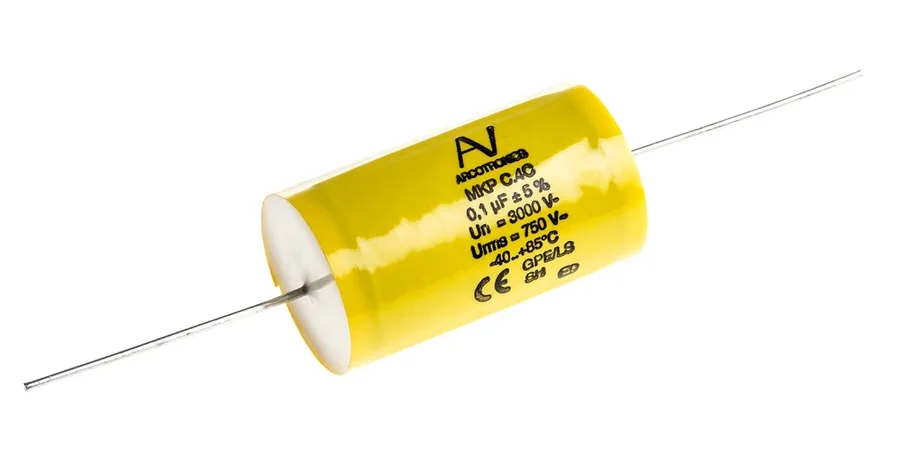

A polypropylene capacitor is a type of film capacitor distinguished by its use of a thin polypropylene film as the dielectric material. This dielectric, positioned between two conductive electrodes, is pivotal in determining the capacitor's performance characteristics. Polypropylene film capacitors are favored for applications demanding high performance, stability, and reliability due to their unique electrical properties.

Film capacitors, in general, utilize a thin plastic film as the dielectric, providing a middle ground in performance and cost compared to other capacitor types like ceramic or electrolytic capacitors. Polypropylene film capacitors stand out within the film capacitor family because of their superior performance in specific applications.

| Characteristic | Polypropylene Capacitor | Ceramic Capacitor | Electrolytic Capacitor |

|---|---|---|---|

| Dielectric Material | Polypropylene Film | Ceramic Material | Electrolyte (liquid or solid) |

| Typical Capacitance Range | Medium to high | Low to medium | High |

| Voltage Rating | Medium to High | Low to Medium | Medium to High |

| Temperature Stability | Excellent | Moderate to Good | Poor |

| Dissipation Factor | Very Low | Low to Medium | High |

| Polarity | Non-polarized | Non-polarized | Polarized (except special types) |

| Cost | Medium to High | Low | Low to Medium |

| Typical Applications | Audio, power supplies, high-frequency circuits | General-purpose, bypass, coupling | Power smoothing, decoupling, energy storage |

Key Characteristics of Polypropylene Capacitors

Polypropylene capacitors are characterized by several key electrical parameters that dictate their suitability for diverse applications. These parameters include capacitance, voltage rating, temperature stability, and dissipation factor, each contributing significantly to the capacitor's performance and reliability.

| Characteristic | Description | Typical Values | Impact on Applications |

|---|---|---|---|

| Capacitance | The ability to store electrical charge. Measured in Farads (F). | Picofarads (pF) to Microfarads (µF) | Determines energy storage capacity; affects tuning, filtering, and timing circuits. |

| Voltage Rating | The maximum voltage the capacitor can withstand without damage. | Tens of volts to Kilovolts (kV) | Ensures reliable operation within a circuit's voltage limits; crucial for power applications. |

| Temperature Stability | How much the capacitance and other characteristics change with temperature. | Very low drift over a wide temperature range | Maintains performance consistency across temperature fluctuations; essential for precision and reliability. |

| Dissipation Factor (DF) | A measure of energy loss within the capacitor, also described as tan δ. Lower DF is better. | 0.0001 to 0.001 (at 1kHz) | Indicates the energy losses of the capacitor due to inherent resistance, affecting signal quality in audio and RF applications. |

Polypropylene vs. Polyester Capacitors: A Detailed Comparison

Polypropylene and polyester capacitors are both popular film capacitors, yet they possess distinct characteristics that make them suitable for different applications. This section provides a detailed side-by-side comparison to help you choose the right capacitor for your needs, focusing on performance, application, and cost considerations.

| Characteristic | Polypropylene Capacitor | Polyester Capacitor |

|---|---|---|

| Dielectric Material | Polypropylene Film | Polyester Film (Polyethylene Terephthalate - PET) |

| Temperature Stability | Excellent, minimal capacitance change with temperature | Good, but more temperature-dependent than polypropylene |

| Dissipation Factor (Loss) | Very low, resulting in high efficiency and less heat generation | Higher than polypropylene, leading to more losses and heat generation |

| Frequency Response | Superior, performing well at high frequencies | Good, but performance degrades at higher frequencies |

| Moisture Absorption | Lower, making them more stable in humid environments | Higher, can affect performance and longevity in humid conditions |

| Voltage Rating | Typically higher voltage ratings available | Generally lower voltage ratings compared to polypropylene |

| Cost | Generally more expensive | Generally less expensive |

| Typical Applications | High-frequency circuits, audio equipment, power supplies where low loss is crucial | General-purpose coupling, decoupling, and bypass applications, less critical timing circuits |

| Longevity | Longer lifespan due to superior stability | Shorter lifespan compared to polypropylene, especially under demanding conditions |

Metallized Polypropylene (MPP) vs. Metalized Polypropylene (MKP)

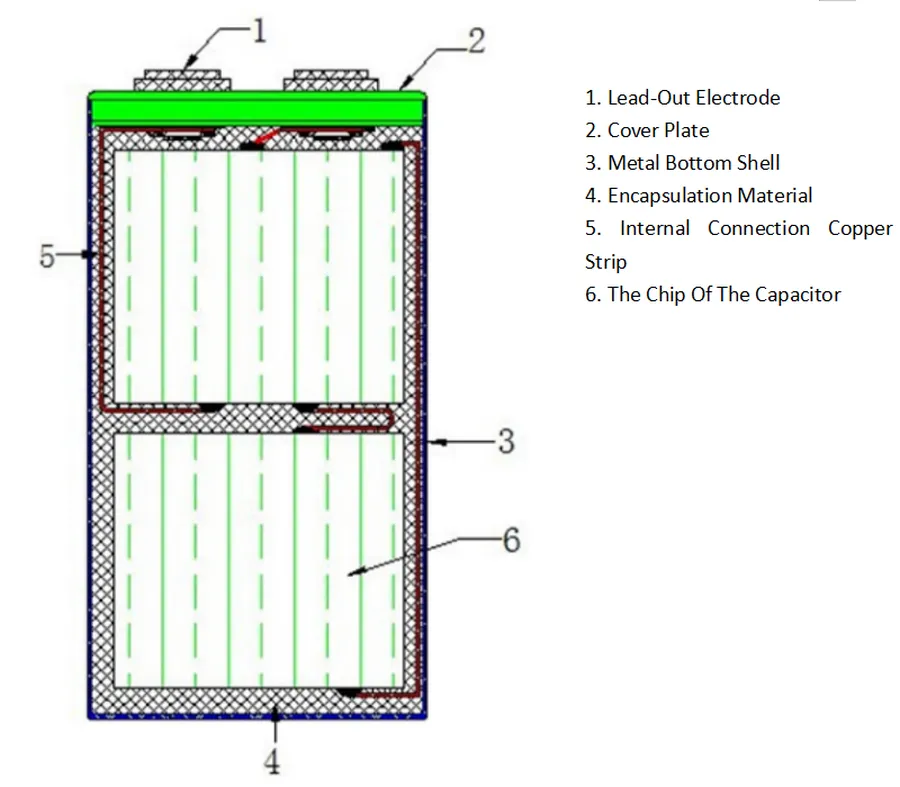

Metallized polypropylene capacitors utilize a thin metal layer directly deposited onto the polypropylene film, differentiating them based on the metal type, typically aluminum (MPP) or zinc-aluminum alloy (MKP), impacting performance characteristics and application suitability.

| Feature | Metallized Polypropylene (MPP) | Metallized Polypropylene (MKP) |

|---|---|---|

| Metallization | Aluminum | Zinc-Aluminum Alloy |

| Self-Healing | Moderate | Excellent |

| Current Handling | Moderate | Good |

| ESR (Equivalent Series Resistance) | Higher | Lower |

| Applications | General purpose, power factor correction | High-frequency applications, audio equipment |

| Cost | Generally lower | Generally higher |

MPP capacitors, with their aluminum metallization, are typically more cost-effective and suitable for general-purpose applications, including power factor correction. MKP capacitors, on the other hand, due to their zinc-aluminum alloy metallization, exhibit superior self-healing properties, lower ESR, and improved high-frequency performance, making them ideal for demanding audio and high-frequency circuit applications. The choice between MPP and MKP capacitors should be based on the application requirements and the desired performance characteristics.

Common Applications of Polypropylene Capacitors

Polypropylene capacitors are utilized across a spectrum of applications, owing to their advantageous electrical properties. Their low dielectric loss, high insulation resistance, and excellent stability make them indispensable in demanding circuits. This section details some of their most common uses, emphasizing the specific roles they fulfill.

- Audio Equipment

In audio circuits, polypropylene capacitors are favored for their ability to handle high-frequency signals with minimal distortion. They are commonly used in crossover networks, signal coupling, and filtering within amplifiers, speakers and other high-end audio equipment, delivering superior clarity and sonic fidelity compared to other capacitor types. Their low dissipation factor prevents signal loss and phase shifts. - High-Frequency Circuits

Polypropylene capacitors are crucial in high-frequency circuits such as those found in RF transmitters and switching power supplies. Their ability to maintain stable capacitance values over a wide frequency range, combined with a low dissipation factor, makes them ideal for filtering and bypass purposes, ensuring efficient and reliable operation with minimum power loss. Their ability to handle high-frequency AC signals with low ESR (Equivalent Series Resistance) is key in these applications. - Power Supplies

These capacitors play an essential role in power supply units by providing stable voltage filtering and smoothing. Due to their robust temperature stability and high reliability, polypropylene capacitors are particularly favored for smoothing voltage ripples and improving the overall efficiency and stability of power conversion stages, ensuring power is delivered consistently and reliably to the connected devices. This application is particularly important in both consumer and industrial grade equipment. - Motor Run Applications

Polypropylene capacitors are commonly used as motor run capacitors for single-phase AC motors due to their reliable performance and high AC voltage handling capabilities. They assist in starting and running the motor by providing the necessary phase shift of the current. The stability and reliability of these capacitors are essential to the proper operation of many single-phase motors, particularly under continuous load applications, such as in pumps, compressors and industrial equipment. Their long lifespan is especially valuable here, reducing the need for frequent replacements.

Advantages of Using Polypropylene Capacitors

Polypropylene capacitors offer a compelling combination of electrical performance characteristics, making them a preferred choice in demanding applications. Their inherent advantages stem from the properties of the polypropylene film dielectric, resulting in superior performance compared to other capacitor types in several key areas.

- Low Dissipation Factor (Low Loss)

Polypropylene capacitors exhibit exceptionally low loss, quantified by a very small dissipation factor (tan δ). This low loss means minimal energy is converted to heat during operation, resulting in higher energy efficiency and less heat generation, which is crucial in power-sensitive circuits. This factor is critical in high-frequency applications and audio circuits where signal integrity is paramount. Typical dissipation factors can range from 0.0001 to 0.001 at 1 kHz. - High Reliability

The robust nature of polypropylene film dielectric provides for a very high reliability and long service life. They are less prone to degradation over time compared to other capacitor types, such as electrolytic capacitors, particularly at higher operating temperatures. The predictable aging characteristics ensure consistent performance throughout the component's lifespan, enhancing the overall reliability of the end product. - Excellent Stability Over Temperature

Polypropylene capacitors demonstrate superior stability of capacitance and other electrical parameters over a wide temperature range. This stability is vital in environments with variable operating temperatures, preventing fluctuations in the circuit performance. Typical operating temperatures range from -40°C to +85°C or even up to 105°C for some specialized types, with minimal changes in capacitance and dissipation factor. This stability is crucial for applications where performance needs to be consistent across temperature variations. - Excellent Stability Over Frequency

The properties of polypropylene capacitors remain very stable across a broad spectrum of frequencies. This excellent frequency response is particularly advantageous in high-frequency and AC circuits, where other capacitor types might exhibit degraded performance at higher frequencies due to internal losses and impedance changes. This stability allows for predictable and consistent performance at various operating frequencies. - High Insulation Resistance

Polypropylene capacitors have very high insulation resistance, which results in a minimal leakage current. This property is essential in circuits where low current leakage is critical to minimize power loss and prevent unwanted interference. High insulation resistance ensures that charge is stored efficiently within the capacitor without significant leakage. - High Voltage and Current Handling Capabilities

Polypropylene capacitors can be constructed to handle high voltage and current levels, making them suitable for applications such as power electronics and motor start/run circuits. These high voltage capabilities are often required in circuits where high peak currents and voltages are expected.

Frequently Asked Questions About Polypropylene Capacitors

This section addresses common questions regarding polypropylene capacitors, aiming to provide clarity on their characteristics, usage, and selection. Understanding these aspects is crucial for effectively utilizing these components in various applications.

- Are polypropylene capacitors polarized?

No, polypropylene capacitors are generally non-polarized. This means they do not have a designated positive or negative terminal and can be connected either way in a circuit. This characteristic simplifies circuit design and installation, as polarity concerns are eliminated. However, it's crucial to check the manufacturer's datasheet, as some specialized capacitors might have a polarity marking for specific mounting configurations. - How long do polypropylene capacitors typically last?

Polypropylene capacitors are known for their long lifespan due to the stability of the polypropylene film dielectric. Under normal operating conditions, they can last for many years, often exceeding 10 years, provided they are not operated beyond their specified voltage and temperature ratings. Factors like excessive heat, voltage spikes, and improper storage can accelerate degradation. The lifetime is also affected by the application's specific conditions. For example, continuous exposure to high ripple current can accelerate aging. - What is the working voltage of a polypropylene capacitor?

The working voltage of a polypropylene capacitor refers to the maximum DC or peak AC voltage it can safely handle during continuous operation. This rating is crucial to prevent dielectric breakdown and ensure reliable performance. Polypropylene capacitors are available with a range of voltage ratings from a few hundred volts to several kilovolts, catering to various application requirements. It is always essential to select a capacitor with a working voltage rating that exceeds the maximum expected voltage in the circuit, and to consider the ripple current and any transient surges that may be present. - How do I select the correct polypropylene capacitor for my application?

Selecting the right polypropylene capacitor requires careful consideration of several factors. First, determine the required capacitance value based on the circuit design. Second, choose a capacitor with a voltage rating that is higher than the maximum voltage expected in the circuit. Third, evaluate temperature and frequency requirements, as these can affect the capacitor's performance. Finally, assess the physical size and mounting method of the capacitor to ensure that it fits within the available space. Consulting manufacturer datasheets and guidelines is essential to verify that all parameters meet the application's specific requirements. - What are the primary advantages of using polypropylene capacitors?

Polypropylene capacitors offer several key advantages, including low dissipation factor (low losses), high insulation resistance, excellent stability over temperature and frequency, and good self-healing properties (especially metallized types). These attributes make them ideal for high-performance applications. The low loss characteristic is particularly useful in applications such as audio, where signal integrity is crucial, and the temperature stability enables consistent performance across a broad thermal range. - What is the difference between MPP and MKP capacitors?

MPP stands for Metallized Polypropylene, and MKP stands for Metallized Polypropylene with a series connection. Both use a polypropylene film as a dielectric material, but differ in their construction. MPP capacitors have a thin layer of metal deposited directly on the polypropylene film, and MKP capacitors have a series metallized layer connected to the capacitor's electrode. MKP capacitors have a higher current handling capability and better reliability, typically offering more robust performance in high-stress applications. MPP capacitors are usually more cost effective and used for general purpose applications where the current requirements aren't as demanding. - What are the common failure modes of polypropylene capacitors?

While polypropylene capacitors are generally reliable, they can fail due to various factors. Common failure modes include dielectric breakdown caused by overvoltage, capacitance drift or loss due to prolonged exposure to excessive temperatures, or damage from mechanical stress or improper mounting. Physical damage to the capacitor can also lead to failure. Additionally, degradation of the electrode material can occur over time, leading to increased equivalent series resistance (ESR) and capacitance loss. Selecting a capacitor with adequate ratings and following proper handling and operating guidelines can mitigate these risks.

Selecting the Right Polypropylene Capacitor

Choosing the correct polypropylene capacitor is critical for optimal circuit performance and reliability. This selection process hinges on understanding the specific demands of the application, carefully matching capacitor characteristics to those needs. Key considerations include capacitance value, voltage rating, tolerance, and physical dimensions, each playing a pivotal role in ensuring the capacitor functions effectively within the intended circuit.

| Parameter | Description | Importance | Considerations |

|---|---|---|---|

| Capacitance Value | The amount of charge the capacitor can store, measured in Farads (F). | Directly impacts the circuit's timing, filtering, and energy storage capabilities. | Select a value that matches the circuit's requirements. Standard values are available, but custom values can be obtained. Values are usually coded with numbers and multipliers to indicated a precise value. |

| Voltage Rating | The maximum voltage the capacitor can safely withstand without damage, specified in Volts (V). | Crucial to prevent capacitor failure due to overvoltage, ensure reliable operation. | Select a voltage rating that exceeds the maximum voltage expected in the circuit by a safety margin, typically 20% to 50%. |

| Tolerance | The acceptable variation in the actual capacitance value from the nominal value, expressed as a percentage (%). | Impacts the accuracy of the circuit operation, especially in precise timing or filtering applications. | Choose a tolerance level that is appropriate for the application. Tighter tolerances lead to more accurate behavior and often cost more. |

| Size and Dimensions | The physical size and shape of the capacitor. | Important for fitting into the available space on the circuit board or equipment. | Consider the available physical space and mounting requirements. Determine if the through hole or surface mount design is required. The physical size may affect the capacitance value. |

| Temperature Coefficient | How the capacitance value changes with temperature changes. | Important for circuits exposed to temperature variations. | Use a capacitor with a stable temperature coefficient for designs that must remain stable over a range of temperatures. |

Handling and Storage Best Practices for Polypropylene Capacitors

Proper handling and storage of polypropylene capacitors are crucial for maintaining their performance and longevity. These components, while robust, can be sensitive to specific environmental factors and physical mishandling, which can lead to degradation and premature failure. Adhering to best practices ensures reliable operation in their intended applications.

- Avoid Physical Damage

Polypropylene capacitors should be handled with care to prevent physical damage. Avoid dropping, bending leads excessively, or applying pressure to the capacitor body. These actions can compromise the internal structure and lead to performance degradation or failure. Use appropriate tools and handling methods when integrating them into circuits. - Temperature Control

Store polypropylene capacitors within their specified temperature range, typically between -40°C to +85°C, unless otherwise noted in the manufacturer's datasheet. Avoid prolonged exposure to temperatures exceeding these limits, which can cause the dielectric material to degrade. Also, avoid rapid and extreme temperature changes during handling and storage to mitigate stress and potential cracking. - Humidity Control

Polypropylene capacitors should be stored in a dry environment to prevent moisture ingress, which can lead to internal corrosion and affect the capacitor's electrical characteristics, such as capacitance and insulation resistance. Recommended humidity levels are typically below 70% relative humidity. Use desiccants in storage containers if necessary. - Minimize Exposure to Corrosive Substances

Avoid exposure to corrosive chemicals and gases, which can react with the capacitor's materials, causing degradation of the leads, terminals, and even the dielectric layer. Store them away from substances such as acids, bases, and solvents. Using sealed containers can prevent exposure to harmful atmospheric elements. - Electrostatic Discharge (ESD) Precautions

While polypropylene capacitors are not as sensitive to ESD as some other components, proper precautions are still necessary. Handle the capacitors in an ESD-protected environment, using grounded wrist straps and anti-static mats, especially during circuit integration. This will prevent potential damage from static buildup. - Proper Storage Packaging

Store polypropylene capacitors in their original packaging or suitable protective containers, which should be clean, dry, and free from contaminants. This practice prevents mechanical stress and safeguards against environmental factors. Avoid stacking them without proper support to prevent lead damage. - Lead Care

Avoid excessive bending or twisting of the capacitor leads. These actions can create stress points, which may lead to failure. If leads need reshaping, use tools designed to avoid undue force, ensuring that any alterations comply with manufacturer recommendations.

The polypropylene capacitor's unique combination of stability, low loss, and versatility makes it a cornerstone of modern electronics. Its ability to perform exceptionally in demanding applications, from audio equipment to power systems, highlights its importance. As technology continues to evolve, the reliability of polypropylene capacitors will ensure that they remain a vital component in countless applications, connecting the dots between innovation and everyday life. Understanding the nuances of their performance is key to effective use, ensuring that circuits operate smoothly and reliably.

AnyPCBA

AnyPCBA