Unveiling the World of Diode LED: From Basics to Applications

From the tiny indicator lights on our electronics to the vibrant displays illuminating our cities, the diode LED, or Light Emitting Diode, has become an indispensable part of modern life. This article demystifies the technology behind this ubiquitous light source, explores its diverse uses, and sheds light on how diode LEDs are reshaping various industries, offering efficiency and innovation.

The Core of Diode LED Technology: How It Works

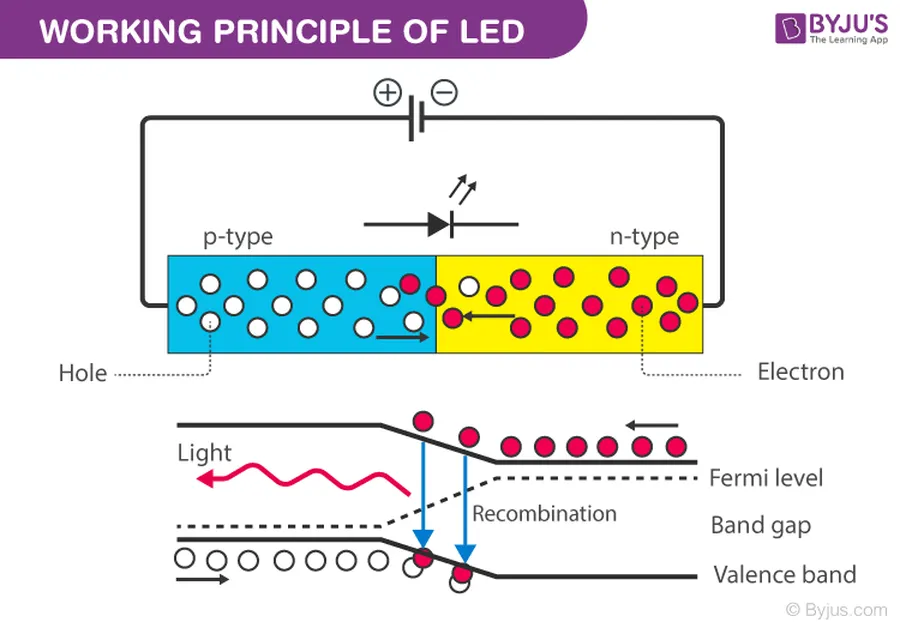

At the heart of Diode LED technology lies the phenomenon of electroluminescence, where light is emitted when an electric current passes through a semiconductor material. This process, fundamentally different from incandescent or fluorescent lighting, is driven by the principles of quantum mechanics and solid-state physics, making LEDs highly efficient and versatile light sources. The core mechanism involves the recombination of electrons and holes within the semiconductor's p-n junction, resulting in the release of photons—the elementary particles of light.

The process can be broken down into the following key steps:

- Material Composition

LEDs are fabricated from semiconductor materials, typically compounds of Group III and Group V elements (e.g., gallium arsenide, gallium nitride). These materials are engineered with specific energy band gaps that dictate the wavelength (color) of emitted light. - P-N Junction Formation

The semiconductor is processed to create a p-n junction. The p-side is doped with impurities that create an excess of electron holes (positive charge carriers), while the n-side has excess electrons (negative charge carriers). - Forward Bias Application

When a voltage is applied in the forward direction (positive to p-side, negative to n-side), electrons from the n-side move across the junction into the p-side, and holes from the p-side move into the n-side. - Electron-Hole Recombination

At the junction, electrons and holes combine. When an electron drops from a higher energy level to fill a hole at a lower energy level, the excess energy is released as a photon, a particle of light. - Light Emission

The wavelength (and therefore the color) of the emitted photon is determined by the energy gap of the semiconductor material. Different materials and dopants produce different colors of light.

Types of Diode LEDs: A Comprehensive Overview

Light Emitting Diodes (LEDs) come in various forms, each designed to cater to specific application requirements. Understanding these different types – through-hole, surface-mount (SMD), chip-on-board (COB), and RGB LEDs – is crucial for selecting the most appropriate LED for a given task. This section provides a comprehensive overview of each type, detailing their characteristics, applications, and advantages.

| LED Type | Description | Advantages | Typical Applications |

|---|---|---|---|

| Through-Hole LEDs | Traditional LEDs with leads that are inserted into holes on a PCB. | Easy to prototype and handle; robust for mechanical stress. | Early electronics projects; indicator lights; legacy systems. |

| Surface-Mount (SMD) LEDs | Small, flat LEDs that are mounted directly onto the surface of a PCB. | Compact size; good heat dissipation; suitable for automated assembly. | Modern electronic devices; mobile phones; automotive lighting; displays. |

| Chip-on-Board (COB) LEDs | Multiple LED chips packaged directly onto a substrate, forming a single light source. | High light output; excellent thermal performance; uniform lighting. | High-intensity lighting; architectural lighting; floodlights; studio lighting. |

| RGB LEDs | LEDs that combine red, green, and blue elements to produce a wide range of colors. | Color flexibility; dynamic lighting effects; customizable color control. | Display screens; decorative lighting; stage lighting; indicator lights. |

Each LED type offers distinct advantages and is better suited for certain applications. Through-hole LEDs, while older technology, are still used for basic projects due to their robustness and ease of handling. SMD LEDs dominate modern electronics because of their small size and good thermal management. COB LEDs are preferred for high-power applications where a concentrated and uniform light source is needed. RGB LEDs provide color flexibility and are widely used in applications requiring dynamic color control. The choice of LED type should always be based on the specific needs of the application, considering factors such as size, brightness, cost, and thermal management.

Key Advantages of Diode LED Lighting Over Traditional Options

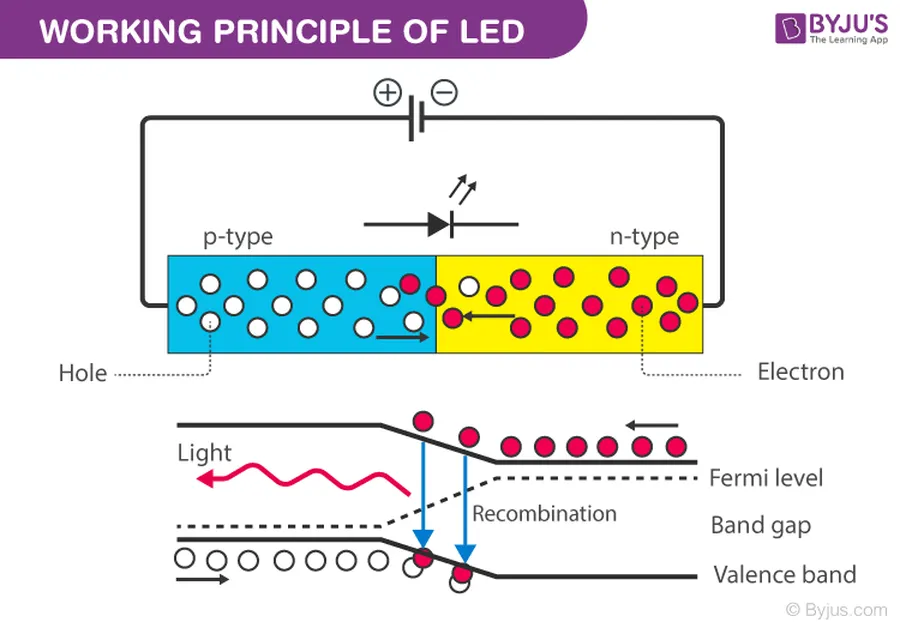

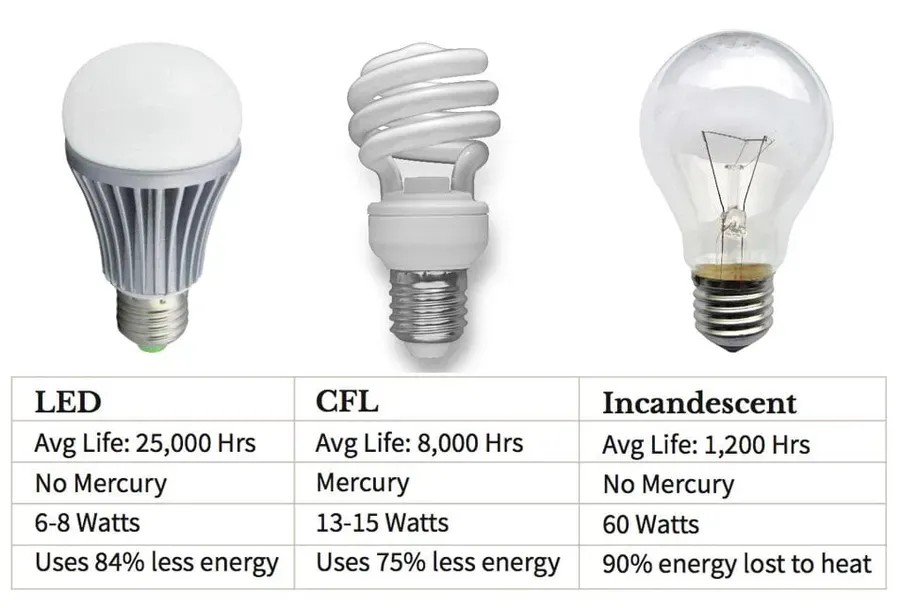

Diode LED lighting presents a compelling alternative to traditional incandescent and fluorescent lighting technologies, primarily due to its superior energy efficiency, extended lifespan, enhanced durability, and reduced environmental impact. These advantages stem from the fundamental differences in how LEDs generate light compared to their predecessors.

| Feature | Diode LED | Incandescent | Fluorescent |

|---|---|---|---|

| Energy Efficiency | High (80-90% of energy converted to light) | Low (5-10% of energy converted to light) | Moderate (20-25% of energy converted to light) |

| Lifespan | Up to 50,000+ hours | 1,000 - 2,000 hours | 8,000 - 10,000 hours |

| Cost | Higher initial cost, lower long-term operating cost | Low initial cost, higher long-term operating cost | Moderate initial cost and operating cost |

| Durability | High (resistant to shock and vibration) | Low (fragile glass bulb) | Moderate (glass tube) |

| Environmental Impact | Low (no mercury, low CO2 emissions) | High (high energy consumption, high CO2 emissions) | Moderate (contains mercury, moderate CO2 emissions) |

Diode LED in Everyday Applications: Beyond Just Lighting

Diode LEDs have revolutionized various sectors, extending far beyond simple illumination to become integral components in numerous everyday devices and systems. Their compact size, energy efficiency, and versatility allow for innovative applications previously unattainable with traditional light sources. From enhancing the visual appeal of consumer electronics to enabling critical medical equipment, diode LEDs are ubiquitous.

Here is a breakdown of how different types of LEDs meet diverse application needs:

- Home Lighting

LEDs have replaced traditional incandescent and fluorescent bulbs, offering energy-efficient and customizable lighting solutions for homes. They are available in a variety of color temperatures and form factors, such as bulbs, strips, and panels, to suit diverse lighting needs. Their long lifespan drastically reduces the need for frequent replacements. - Automotive Lighting

LEDs are now standard in automotive headlights, taillights, and interior lighting. Their fast response time and high brightness contribute to safety, while their small size enables design flexibility. They also facilitate advanced features like adaptive headlights and dynamic turn signals. - Electronic Displays

LEDs are fundamental to modern displays, including televisions, computer monitors, smartphones, and tablets. Their ability to produce bright, vibrant colors, coupled with low power consumption, makes them ideal for these applications. Different LED configurations such as backlighting and direct-view arrays cater to different display sizes and performance needs. - Medical Equipment

In healthcare, LEDs are crucial in medical imaging, surgical lighting, and diagnostic devices. Their precise light output and low heat generation make them ideal for applications requiring accurate and controlled illumination. For example, endoscopy relies on the small form factor and bright light to enhance the view inside the human body. - Industrial Settings

LEDs are widely adopted in industrial environments for task lighting, safety lighting, and signaling. They withstand harsh conditions, resist vibrations, and are energy-efficient. Applications include warehouse lighting, machine lighting, and process control systems. LED displays also provide information and status in manufacturing plants. - Specialized Applications

Beyond mainstream applications, LEDs are also used in specialized areas such as horticulture for plant growth, in UV sterilization equipment, and for communication technologies like Li-Fi (Light Fidelity). Their customizable light spectra and efficiency make them ideal for emerging fields. LEDs are used in photography to provide consistent lighting.

Diode LED Color and Temperature: Understanding the Nuances

Understanding the color and temperature characteristics of diode LEDs is crucial for selecting the appropriate lighting for specific applications. This involves comprehending color temperature, measured in Kelvin (K), the Color Rendering Index (CRI), and how these factors influence the perceived color and quality of light.

| Characteristic | Description | Impact |

|---|---|---|

| Color Temperature | Measured in Kelvin (K), describes the warmth or coolness of the light. | Lower Kelvin values (2700-3200K) produce a warm, yellowish light, suitable for cozy environments. Higher Kelvin values (5000-6500K) produce a cool, bluish-white light, ideal for task lighting. |

| Color Rendering Index (CRI) | A scale from 0 to 100 that measures how accurately a light source renders the colors of objects compared to a natural light source. | Higher CRI values (80+) indicate more accurate color rendering, which is important for applications where color accuracy is essential, such as art galleries or retail displays. |

| Color Mixing | The process of combining different colors of LEDs to achieve a desired hue or white light. | RGB LEDs allow for dynamic color changes, while white light can be created by combining different phosphor materials or through mixing LEDs emitting different colors. |

The Kelvin scale categorizes light from warm (lower values) to cool (higher values). For instance, incandescent light typically falls around 2700K, while daylight might be around 5500-6500K. Choosing the right color temperature depends on the intended environment and purpose. Warm light promotes relaxation, while cool light enhances focus and visibility. CRI, on the other hand, indicates the quality of the light source in terms of color accuracy. A high CRI means that colors will appear vibrant and true under the light. Color mixing in LEDs provides versatility, enabling dynamic color changes and customized lighting solutions.

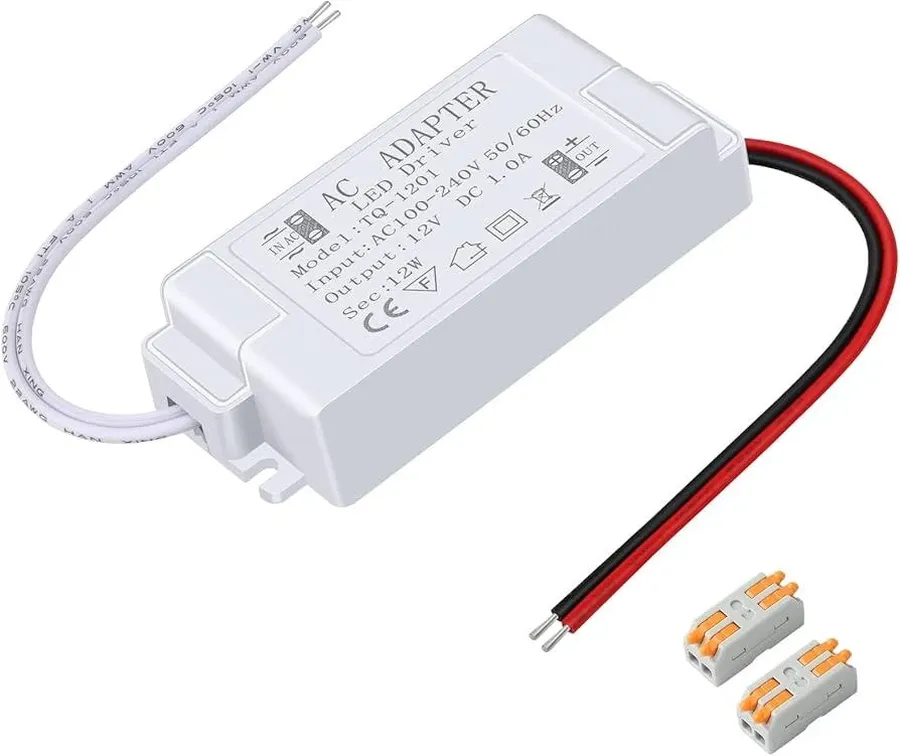

Diode LED Drivers: Powering the Light

Diode LED drivers are essential components in any LED lighting system, acting as the power supply that regulates the electrical current and voltage to ensure optimal LED performance and longevity. Unlike traditional light sources, LEDs require a stable, constant current to operate efficiently and avoid damage. Drivers convert the incoming power source, typically AC, to the appropriate DC current and voltage needed by the LEDs.

The primary function of an LED driver is to provide a constant current, regardless of variations in the input voltage or LED forward voltage drops. This constant current is crucial because even slight fluctuations in current can lead to significant changes in light output and can degrade or burn out the LEDs prematurely. The driver's secondary, but crucial function, is to perform AC-to-DC conversion and provide voltage regulation.

| Driver Type | Current Output | Voltage Output | Typical Application | Advantages | Disadvantages |

|---|---|---|---|---|---|

| Constant Current Driver | Regulated, consistent current | Variable, adjusts to LED load | Most LED Lighting | Optimal LED protection and longevity | Can be more expensive |

| Constant Voltage Driver | Variable, dependent on LED load | Regulated, fixed voltage | LED strips and tape lights | Cost-effective, simple | Requires specific LED compatibility |

| Dimmable Driver | Regulated, can adjust current output | Variable, adjusts to LED load | Any dimmable LED application | Flexibility in light intensity | Can be more complex to configure |

LED drivers come in various types and configurations to suit different applications. Constant current drivers are predominantly used to maintain stable brightness and lifespan, especially in applications requiring specific light output consistency, such as residential lighting and commercial settings. Constant voltage drivers are more often used with LED strips or tape lights where a specific voltage level is needed, and current is managed by the specific circuit design of the strip. Dimmable drivers add further flexibility with light output modulation, allowing for adjustable illumination and energy savings. Regardless of the chosen driver type, it must match the voltage and current requirements of the LEDs to ensure optimal performance and longevity. AC-to-DC conversion is a prerequisite to use most wall power circuits, and drivers are built in or can be purchased as separate power supplies to do this.

Diode LED Tape Light: Versatility in Illumination

Diode LED tape lights, also known as LED strip lights, represent a highly versatile and adaptable lighting solution, characterized by their flexible circuit board embedded with numerous small LEDs. Their inherent flexibility, ease of installation, and customizable nature make them suitable for a broad spectrum of applications, extending beyond conventional lighting fixtures.

- Flexibility

The flexible nature of LED tape lights allows for installation in curved and irregular spaces, providing lighting solutions where rigid fixtures are unsuitable. The base material is typically a thin, flexible printed circuit board (PCB) which can be bent and manipulated. - Installation

LED tape lights are generally easy to install due to their adhesive backing, often using 3M adhesive. This eliminates the need for complex mounting hardware, though additional clips or supports might be necessary in certain environments or for longer runs. The user can install the strip and peel off the adhesive backing without the need for other tools. - Customization

Tape lights can be easily cut to desired lengths at designated points (usually marked with scissors symbols) using basic scissors or a blade. They are available in various colors, brightness levels, and color temperatures, offering substantial customization potential to match specific requirements. Furthermore, dimming capabilities can be introduced for added flexibility. - Suitable Applications

LED tape lights find extensive use in both residential and commercial settings. These include under-cabinet lighting, cove lighting, accent lighting, and backlighting for signs and displays. Furthermore, they are ideal for task lighting in workspaces and can be integrated into furniture or architectural elements to achieve a unique aesthetic or increase functionality.

| Feature | Description | Advantages | Considerations |

|---|---|---|---|

| Adhesive Backing | Usually 3M adhesive. | Easy installation, no screws required. | Adhesive may fail on certain surfaces, need for additional clips in some cases. |

| Cutting Points | Designated cut marks, usually every few LEDs. | Length adjustment for custom installations. | Cutting at incorrect points may damage the strip. |

| Flexibility | Can be bent to follow contours. | Adaptable to irregular surfaces. | Excessive bending can cause damage over time. |

| Powering | Requires an LED driver/power supply. | Low voltage operation is generally safer. | Need to match voltage/current requirements and calculate total load |

| Colors & Brightness | Available in various colors and brightness levels. | Wide range of customization options. | Color accuracy may vary between brands and batches. |

The versatility of LED tape lights, combined with their energy-efficient nature, makes them an attractive option for both functional and decorative lighting applications, offering a high level of flexibility and ease of use to the end user.

Frequently Asked Questions About Diode LEDs

This section addresses common questions regarding diode LEDs, offering clarity on their lifespan, environmental impact, recyclability, dimming capabilities, and safety considerations. We also delve into heat dissipation and potential hazards associated with these lighting solutions, providing a comprehensive understanding for both general users and those with specific application needs.

- How long do diode LEDs typically last?

The lifespan of a diode LED is significantly longer than traditional incandescent or fluorescent lights, typically ranging from 25,000 to 100,000 hours. This translates to many years of use, even with regular operation. The actual lifespan can be affected by factors such as operating temperature, current levels, and the quality of the LED itself. Reputable manufacturers often specify expected lifespan in their product literature. - Are diode LEDs environmentally friendly?

Yes, diode LEDs are generally considered more environmentally friendly than traditional lighting options. They are highly energy-efficient, consuming significantly less power for the same light output, which reduces greenhouse gas emissions from electricity generation. Furthermore, LEDs do not contain harmful substances such as mercury, unlike fluorescent bulbs, making them safer for disposal. Their longevity also reduces the need for frequent replacements, minimizing waste. - Can diode LEDs be recycled?

While not all components of a diode LED are easily recyclable, many parts can be. The metallic elements in the heat sink and the circuit boards can be recovered. The LED chips themselves are more challenging due to their composition but are subject to ongoing research for improved recovery processes. Check local guidelines for proper disposal as the regulations vary by region. - Are diode LEDs dimmable?

Many diode LEDs are dimmable, but it's crucial to use a compatible LED dimmer switch. Not all dimmers designed for traditional lighting work well with LEDs and might cause flickering or shortened lifespan. Always verify the dimmer compatibility with the LED specifications provided by the manufacturer. Some LEDs have internal circuitry and other designs that may preclude proper dimming. - What are the safety considerations for diode LEDs?

Diode LEDs produce very little heat compared to incandescent bulbs, making them safer to touch. However, proper handling is still necessary, particularly with high-power LEDs, which may require heat sinks for effective thermal management. Furthermore, always ensure the correct driver or power supply is used, or the diodes may fail or overheat. Always install according to all local and national electrical codes. - How does heat dissipation affect diode LED performance and lifespan?

Heat management is crucial for LED performance. Excessive heat can degrade the performance and shorten the lifespan of the LED. In efficient thermal designs, the heat generated by the LEDs is dissipated via heat sinks and heat-conductive materials. Effective heat dissipation is essential for sustaining the luminous output, color consistency, and longevity of diode LEDs. - Are there any potential hazards associated with diode LEDs?

While generally safe, some potential hazards exist. Direct exposure to high-intensity LED light can cause eye discomfort or temporary vision problems, particularly with blue-rich LEDs. Additionally, using the wrong power supply could result in overheating or fire risks. Always ensure proper installation and adhere to safety guidelines provided by the manufacturer and any local regulations.

The Future of Diode LED Technology: Innovations and Trends

The field of Diode LED technology is rapidly evolving, with innovations continually pushing the boundaries of light quality, energy efficiency, and application possibilities. This section explores the emerging trends that are set to redefine the future of illumination, display, and beyond.

- Organic Light Emitting Diodes (OLEDs)

OLEDs represent a significant advancement, offering superior contrast ratios, wider viewing angles, and the ability to create flexible and transparent displays. Their self-emissive nature eliminates the need for backlighting, enabling ultra-thin form factors and reduced energy consumption. Applications extend from high-end television screens and mobile devices to innovative lighting solutions. - Micro-LEDs

Micro-LEDs consist of microscopic LEDs arranged in an array, providing high brightness, high dynamic range (HDR), and exceptional contrast. They offer potential in displays ranging from wearables to large format screens while potentially reducing energy consumption compared to other technologies. Their development focuses on mass transfer and manufacturing techniques to bring down cost and improve yields. - Advanced Control Systems

The integration of sophisticated control systems is revolutionizing the way LEDs are managed. These systems include smart dimming, color tuning, and dynamic light management, enabling granular control over light output based on time of day, usage patterns, or environmental conditions. Wireless connectivity and AI driven algorithms are becoming standard, enhancing personalization and energy conservation. - Integration with Smart Home Technologies

LED lighting is increasingly integrated into smart home ecosystems. This includes voice-controlled lights, sensors for presence detection, and automated lighting schedules based on individual needs and preferences. Furthermore, LEDs are used as data transmitters using Visible Light Communication (VLC), enabling new functionalities within smart environments. - Advancements in Light Quality

Ongoing research focuses on improving light quality metrics, such as color rendering index (CRI) and color consistency, pushing beyond current standards and allowing for applications where accurate color reproduction is critical. New phosphors and nano materials are enabling more efficient and spectrally rich light sources that closely match natural daylight, with research moving towards improved spectrum and circadian cycle adjustment. - Improved Energy Efficiency

Research and development are continuously lowering energy consumption and raising efficiency with new generations of LED materials and designs. The goal is to reduce the carbon footprint of lighting by utilizing alternative substrates, materials, and improved circuit design that can dramatically increase the efficacy of LEDs while reducing their energy requirements. New research involves the exploration of novel materials like perovskites.

In conclusion, the diode LED is far more than just a tiny light source; it's a groundbreaking technology driving innovation across numerous sectors. From its remarkable efficiency and lifespan to its versatility, the diode LED continues to illuminate the path toward a brighter and more sustainable future. As technology advances, expect even more innovative applications of diode LEDs to reshape our world, promising improved performance, affordability, and environmental friendliness.

AnyPCBA

AnyPCBA